You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Built 4t65e - The results are in.

- Thread starter BrandonHall10

- Start date

Turbocharged400sbc

New member

Re: Built 4t65e - Quality takes time

summit had a clearance special on the earls billet ford filter stand/housing. some blemished machining on the one I got but it'd work fine

the moroso ford filter or any of the race filters would be plenty of flow and still filter finer than the oem pump inlet "sock"

summit had a clearance special on the earls billet ford filter stand/housing. some blemished machining on the one I got but it'd work fine

the moroso ford filter or any of the race filters would be plenty of flow and still filter finer than the oem pump inlet "sock"

BrandonHall10

Solving problems

Re: Built 4t65e - Quality takes time

Haha! There's a lot going on there. Thanks for pointing out something that might have been missed.

Certainly a possibility down the road. With the standalone cooler already plumbed, it wouldn't be too difficult. You guys just run a standard automotive oil filter?

Good to see...I concentrated on only page 5 today

Haha! There's a lot going on there. Thanks for pointing out something that might have been missed.

Pit any thought to a external remote filter as well? I have plenty of info if you're intrested

Certainly a possibility down the road. With the standalone cooler already plumbed, it wouldn't be too difficult. You guys just run a standard automotive oil filter?

BrandonHall10

Solving problems

Re: Built 4t65e - Quality takes time

Thanks James. That answers my question. Good point on the filter vs sock. Filter = microns, sock = thousandths (?) Anything that keeps that clutch paste out of the valve body has to be a good thing.

the moroso ford filter or any of the race filters would be plenty of flow and still filter finer than the oem pump inlet "sock"

Thanks James. That answers my question. Good point on the filter vs sock. Filter = microns, sock = thousandths (?) Anything that keeps that clutch paste out of the valve body has to be a good thing.

MyLittlePony

New member

Re: Built 4t65e - Quality takes time

It's ok essentially the RB series stuff is Nissan inline 6 engines, they sold some in Australia they are 3 liter engines designed to compete with the 2JZ engine from Toyota (350 GM versus 351 Ford)... Essentially I am just looking for a manual transmission from a mid 90s skyline, the non GTR trans is grea tto rebuild to hold gobs of power, I am shooting to make mine good for 1000hp, yet only shooting for 800 to the crank.

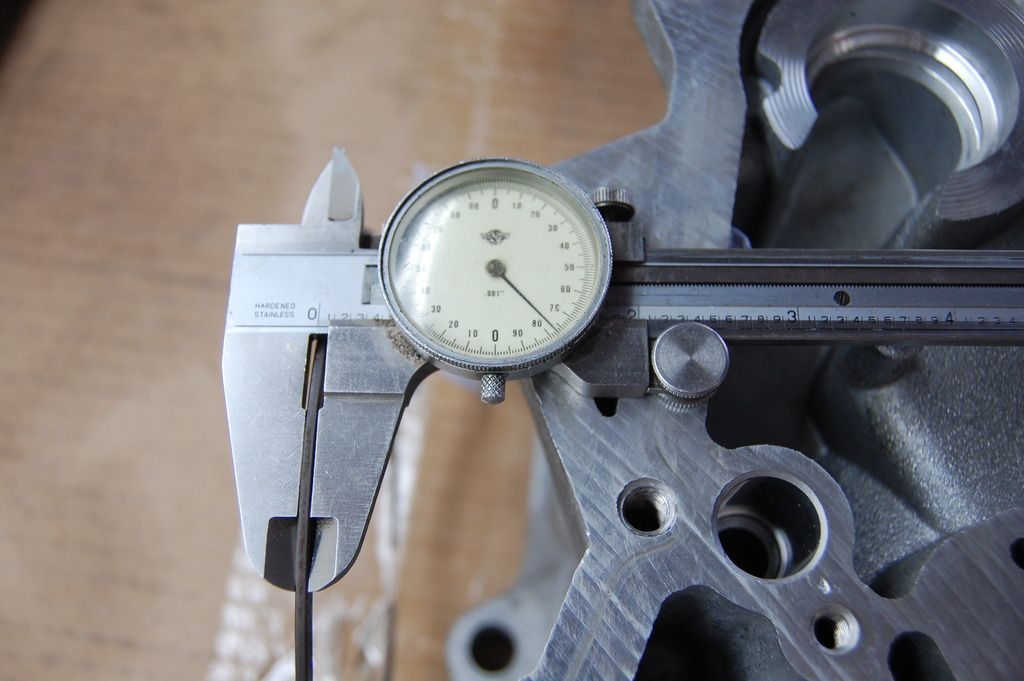

Now back to you, I seriously love reading this thread daily for more beautiful transmission pictures. Very nice indeed man, I do like your methods and how you check everything, never hurts to double check.

I didn't understand half of what you just said. :th_laugh-lol2:

It's ok essentially the RB series stuff is Nissan inline 6 engines, they sold some in Australia they are 3 liter engines designed to compete with the 2JZ engine from Toyota (350 GM versus 351 Ford)... Essentially I am just looking for a manual transmission from a mid 90s skyline, the non GTR trans is grea tto rebuild to hold gobs of power, I am shooting to make mine good for 1000hp, yet only shooting for 800 to the crank.

Now back to you, I seriously love reading this thread daily for more beautiful transmission pictures. Very nice indeed man, I do like your methods and how you check everything, never hurts to double check.

BrandonHall10

Solving problems

Re: Built 4t65e - Quality takes time

Now that I understand. Sounds like a blast!

Hey, I really appreciate that. My methods go back to my tool and die training. Perfection is the standard. Honestly, part of the reason behind all the pictures is records keeping. It's an easy way to remember exactly what I did. Only takes a couple extra minutes to type up some text and post the pictures. Maybe it will help someone along the way too.

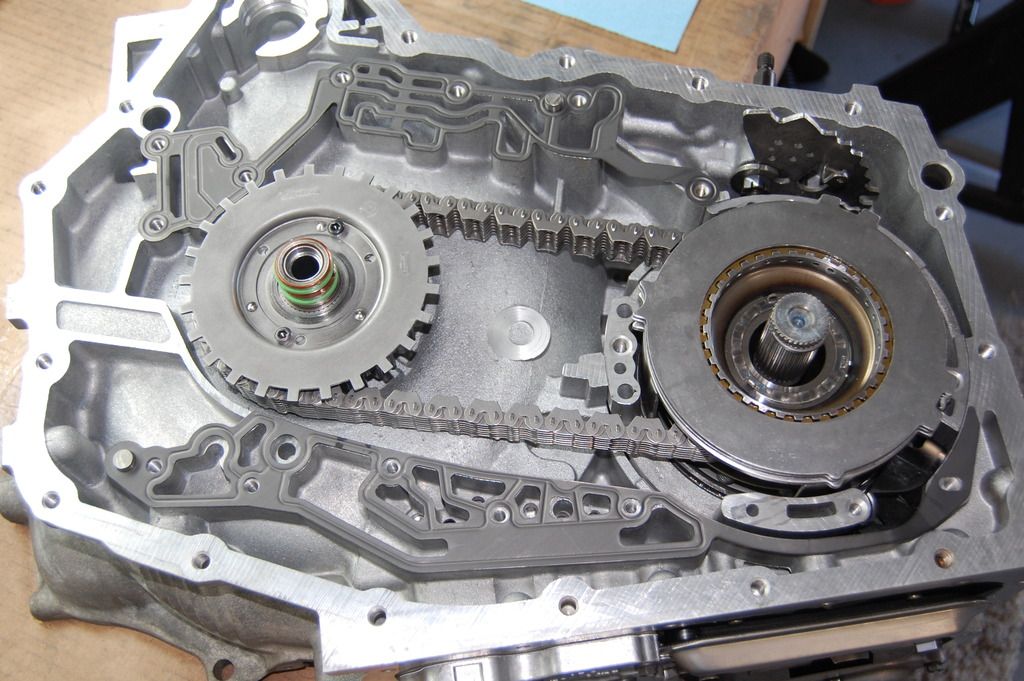

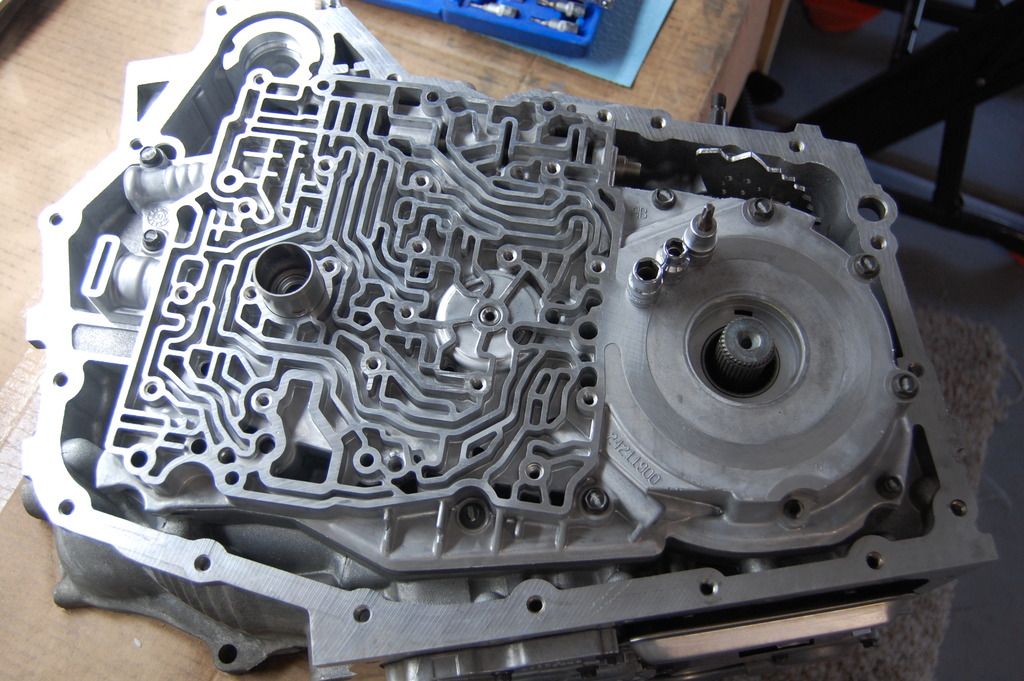

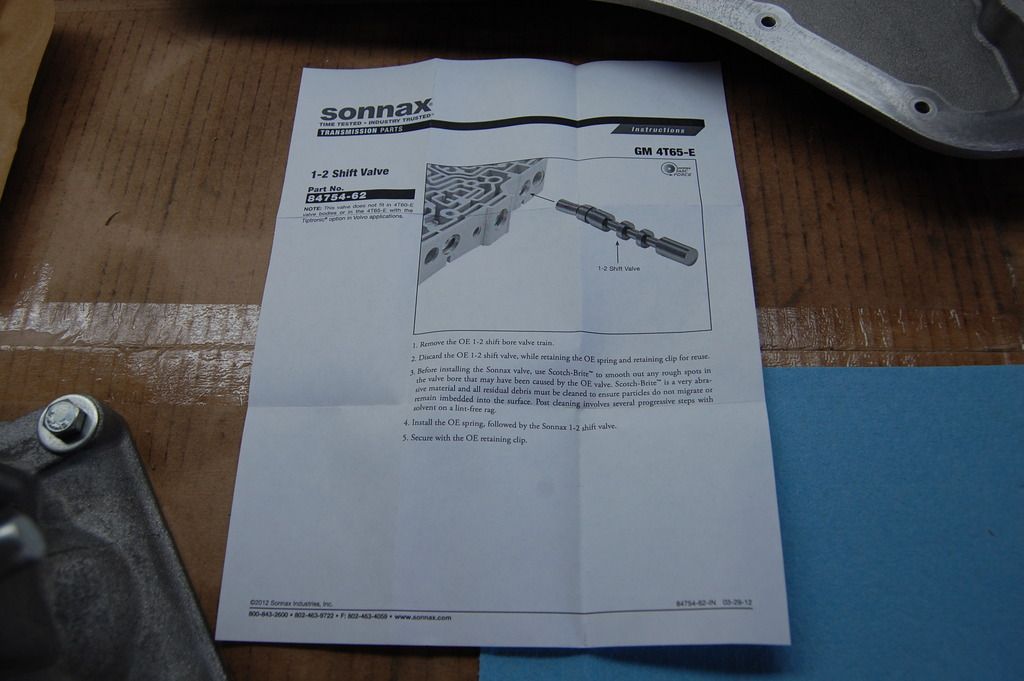

Today was a big day for parts. Things happened at work so I was able to get to the trans shop a day early. 1-2 shift valve, 4th hub, and my super special snap ring showed up!

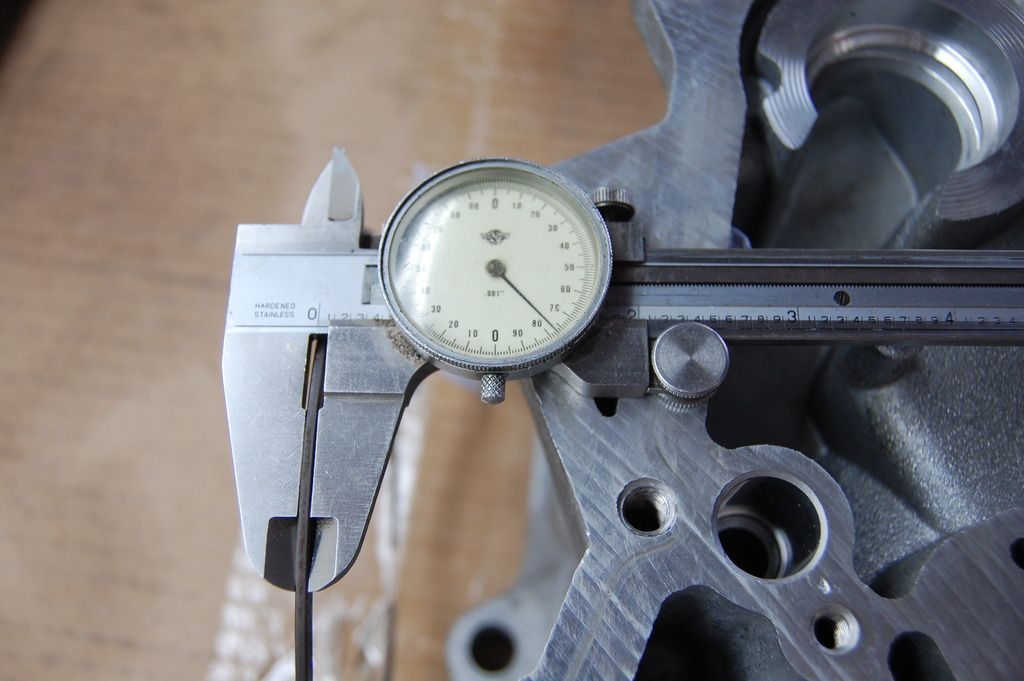

Price ended up being under $6, so I took it, even though I won't need it on this build. I honestly don't know what makes this snap ring special. The only thing I can think is maybe it's thicker than normal? I don't have another to compare it to. Someone willing to measure one they have sitting around? This one measures 0.077". Give or take...

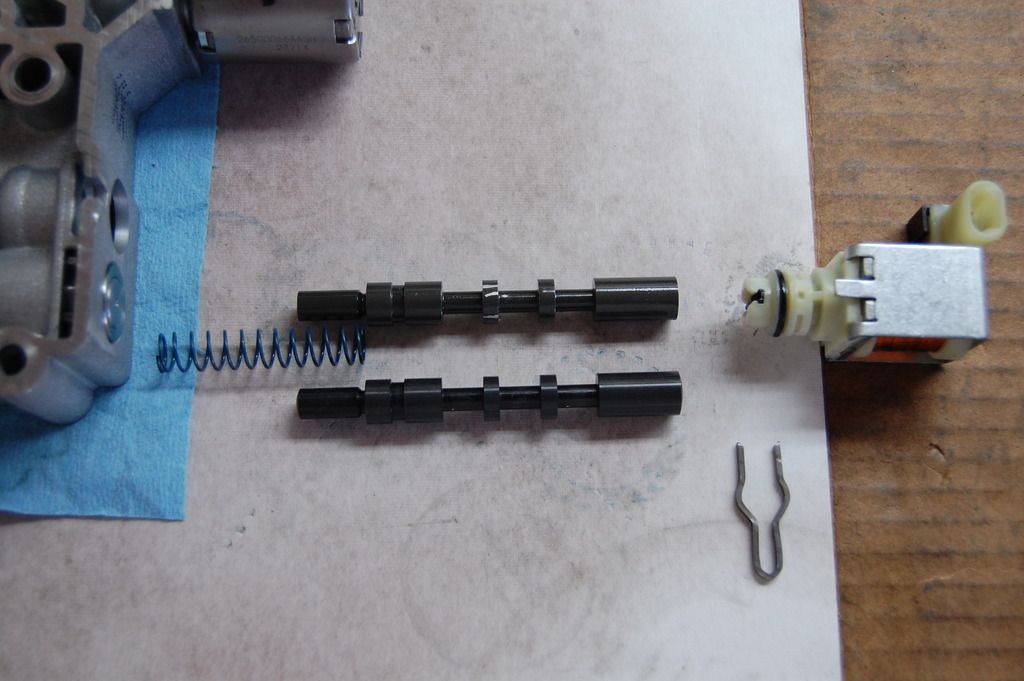

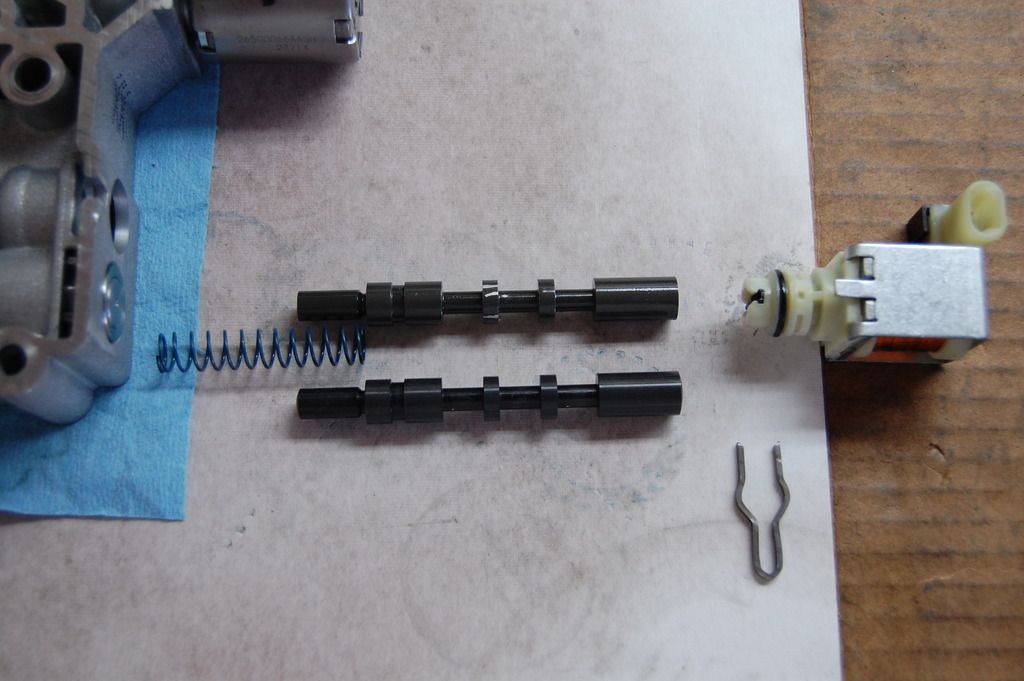

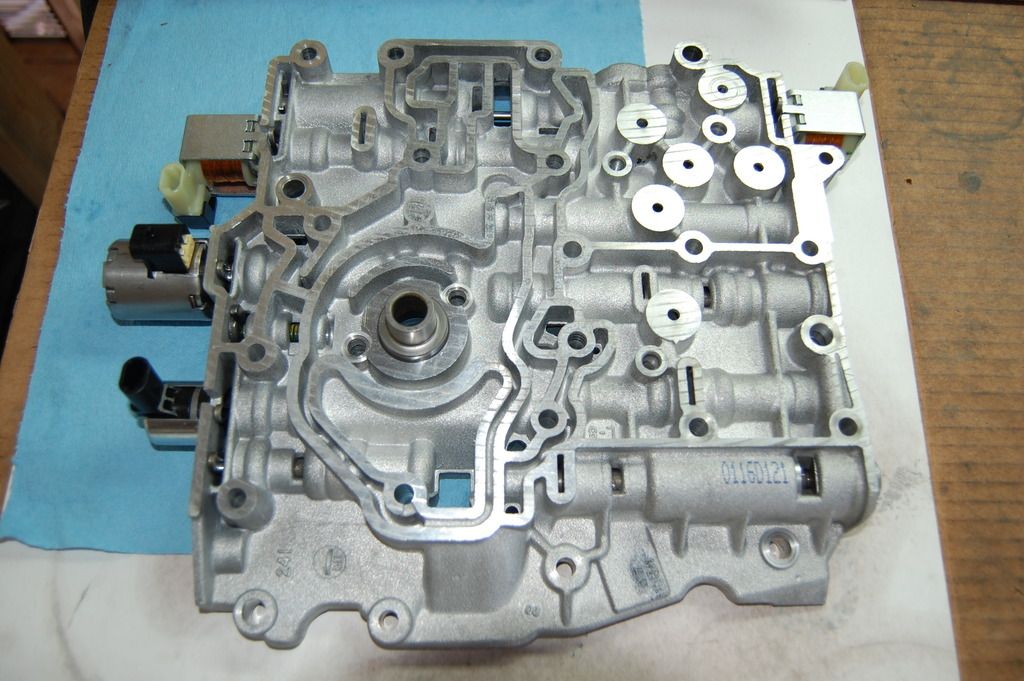

Fresh valve and solenoid vs old scarred one

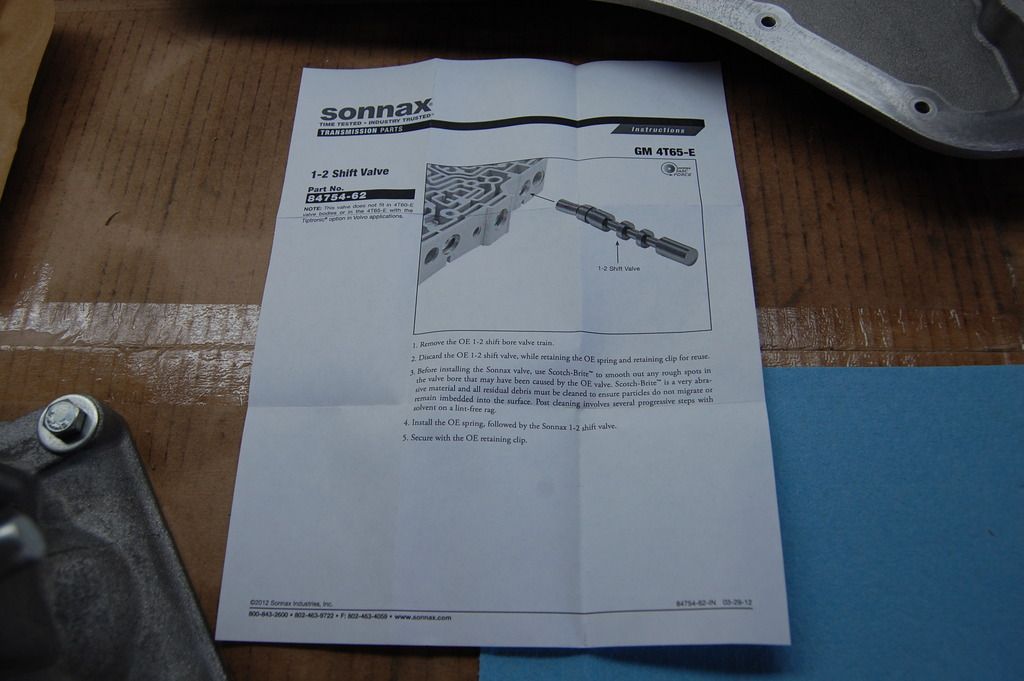

And it comes with instructions. Not sure why. If you're this far into a trans, shouldn't you have a manual on hand?

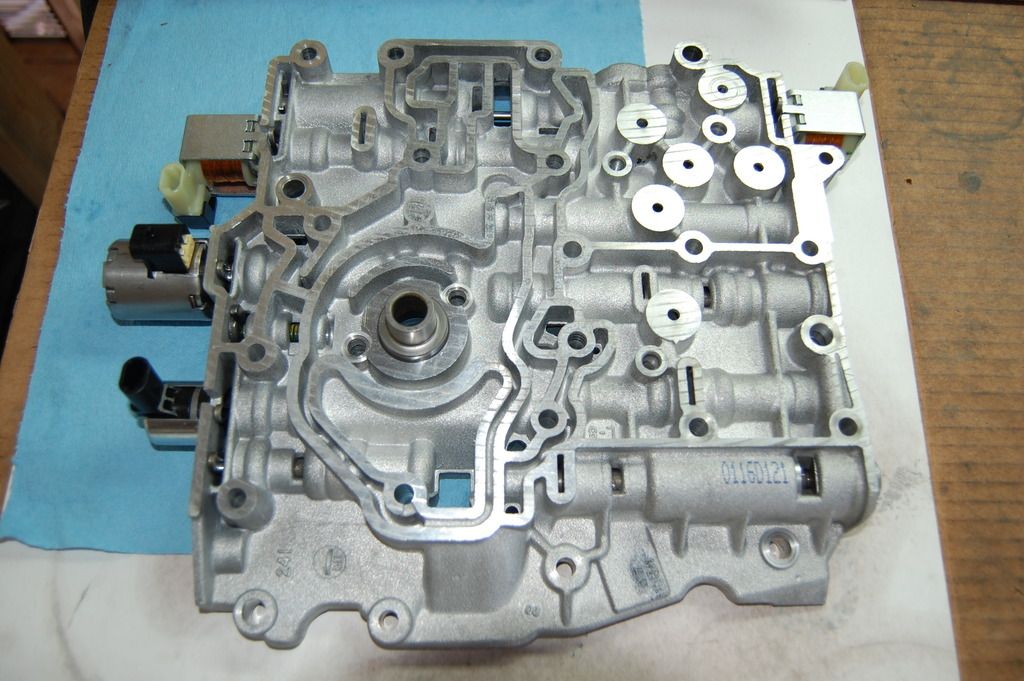

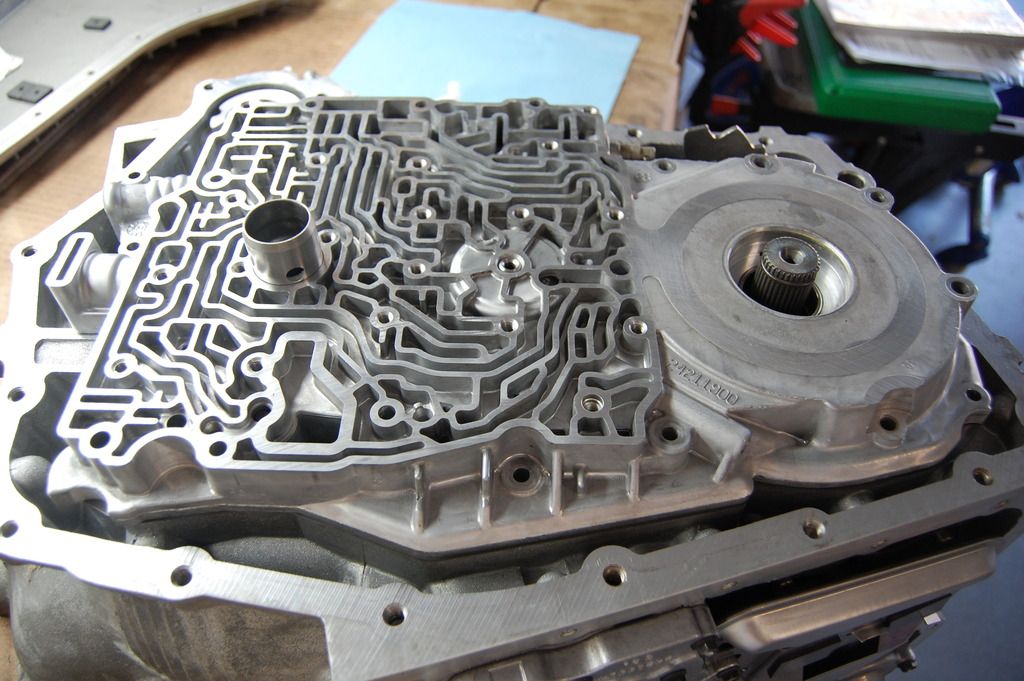

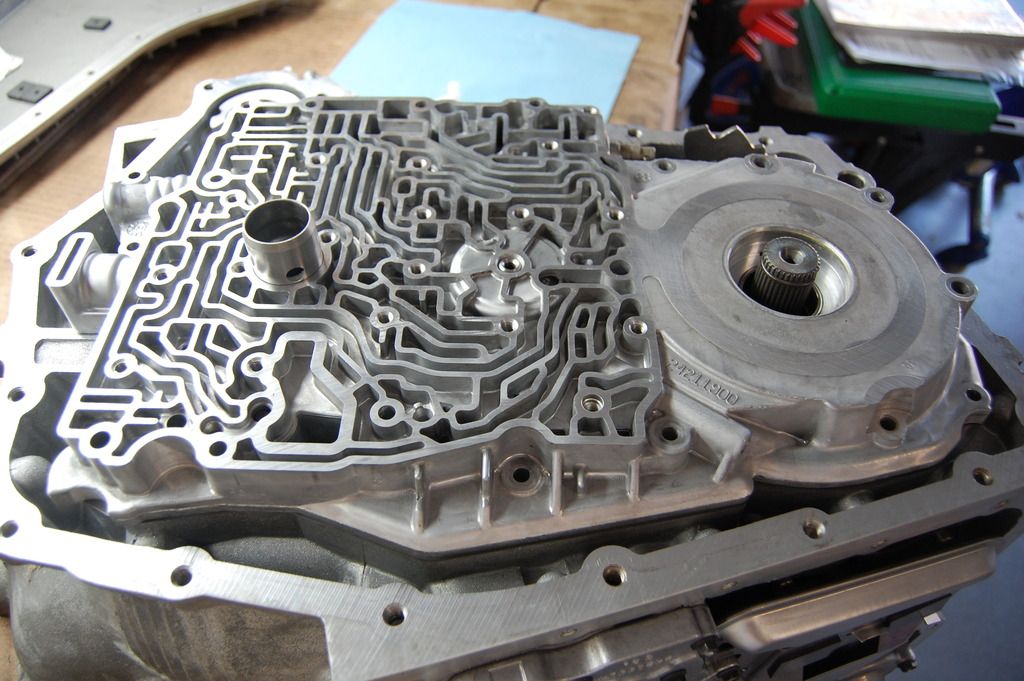

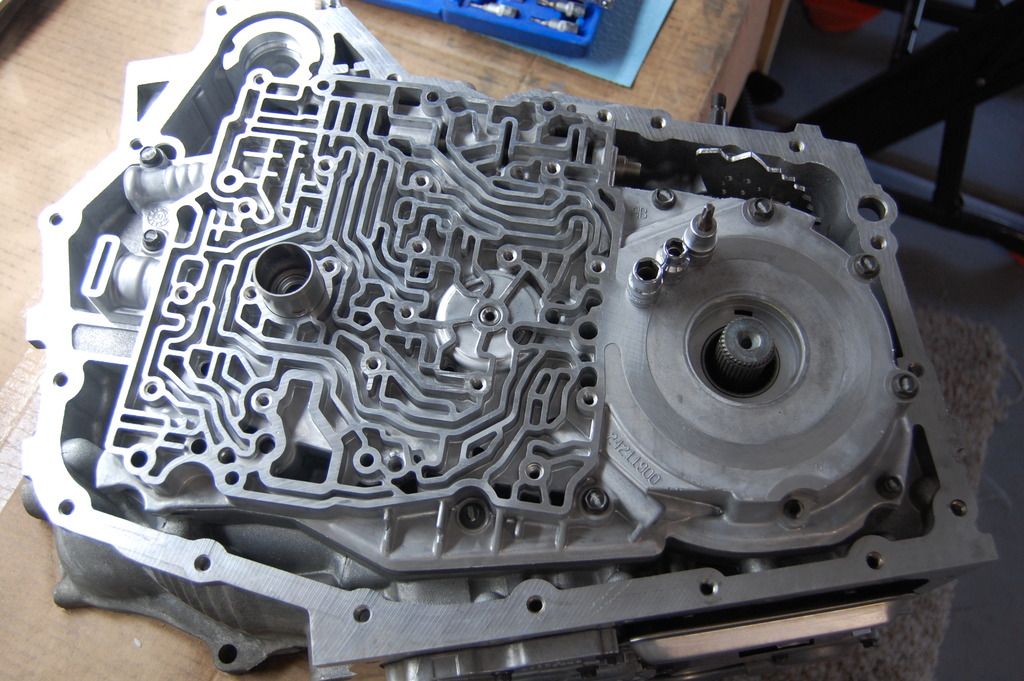

With that, the valve body is finally complete. Waiting for final assembly

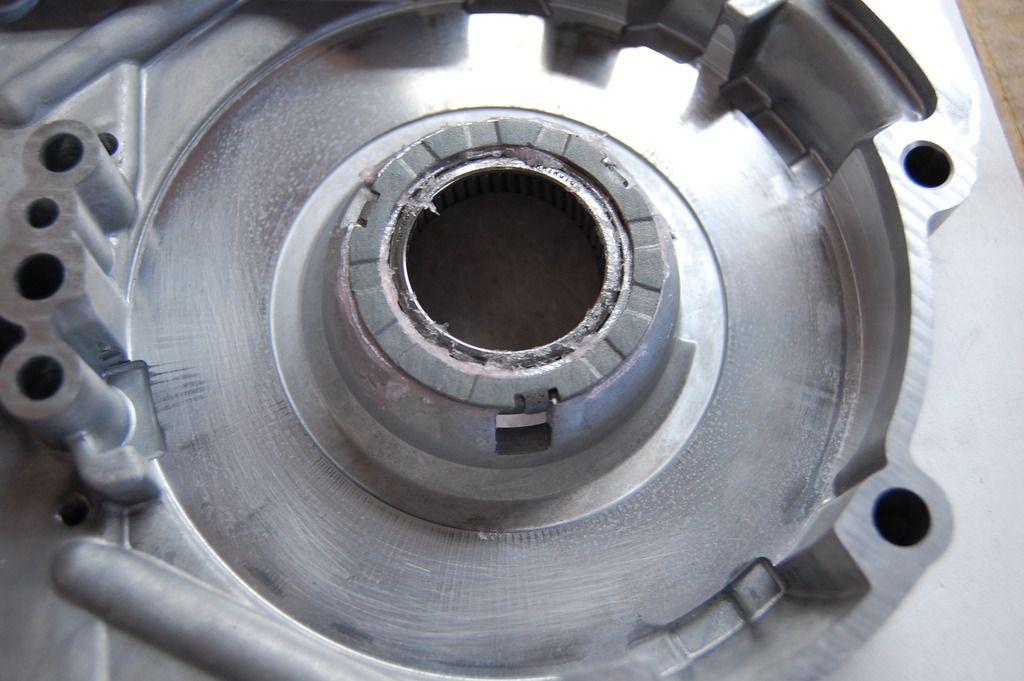

Next step was the 4th hub. Didn't want to go all the way down. It's not uncommon for pressed bushings to close up a bit. You can see where the land on the hub shaft was rubbing hard

Hit the shiny spots with some 600 grit. Took a couple times, but eventually it dropped in.

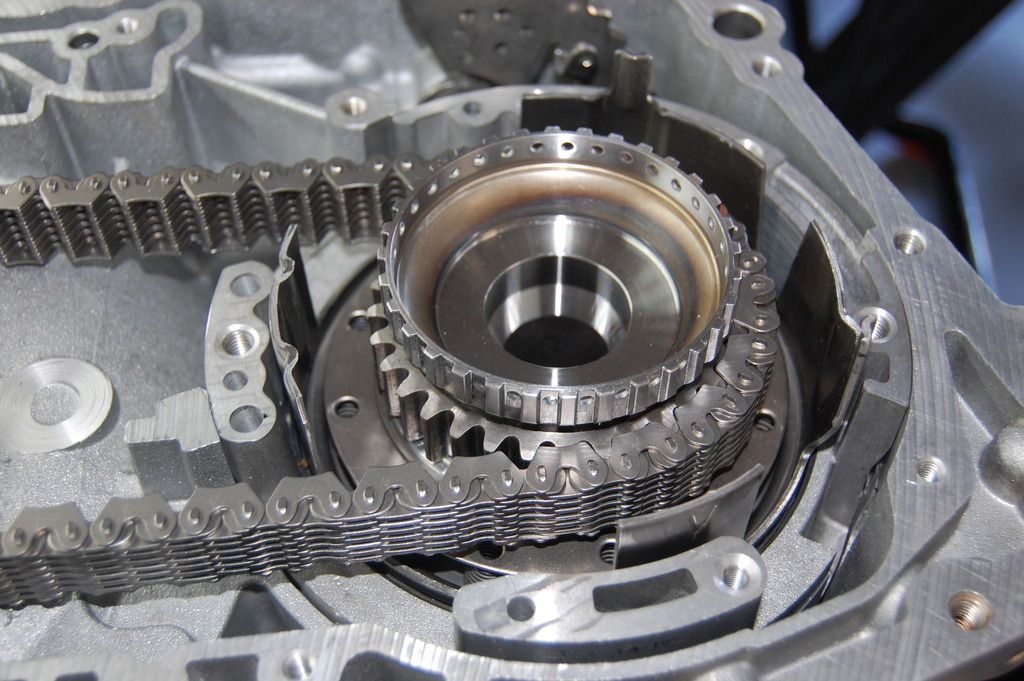

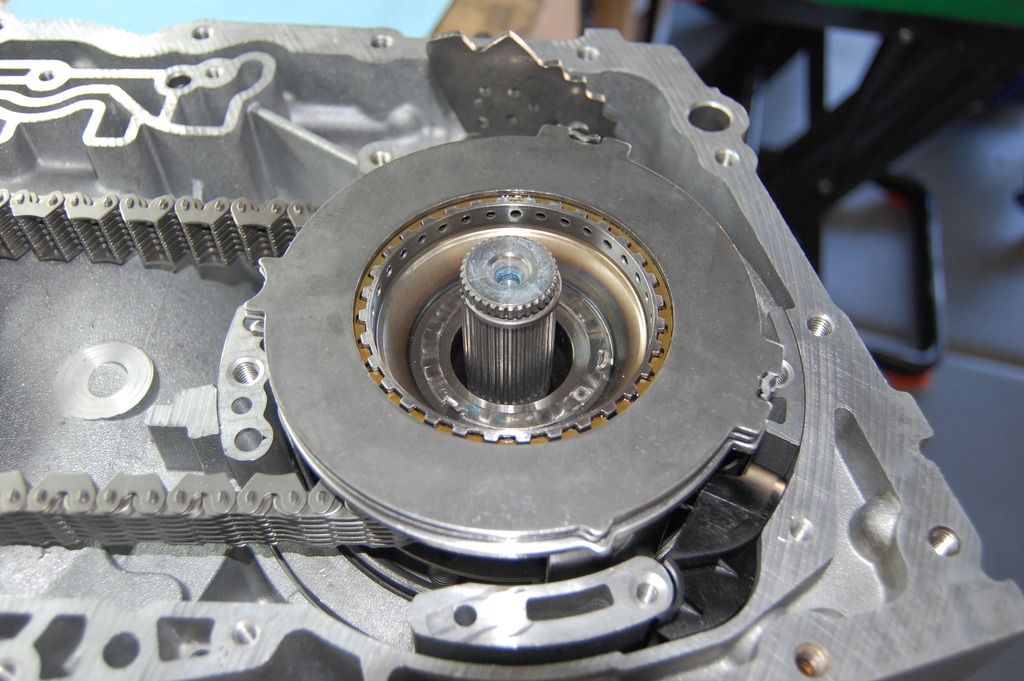

4th stackup

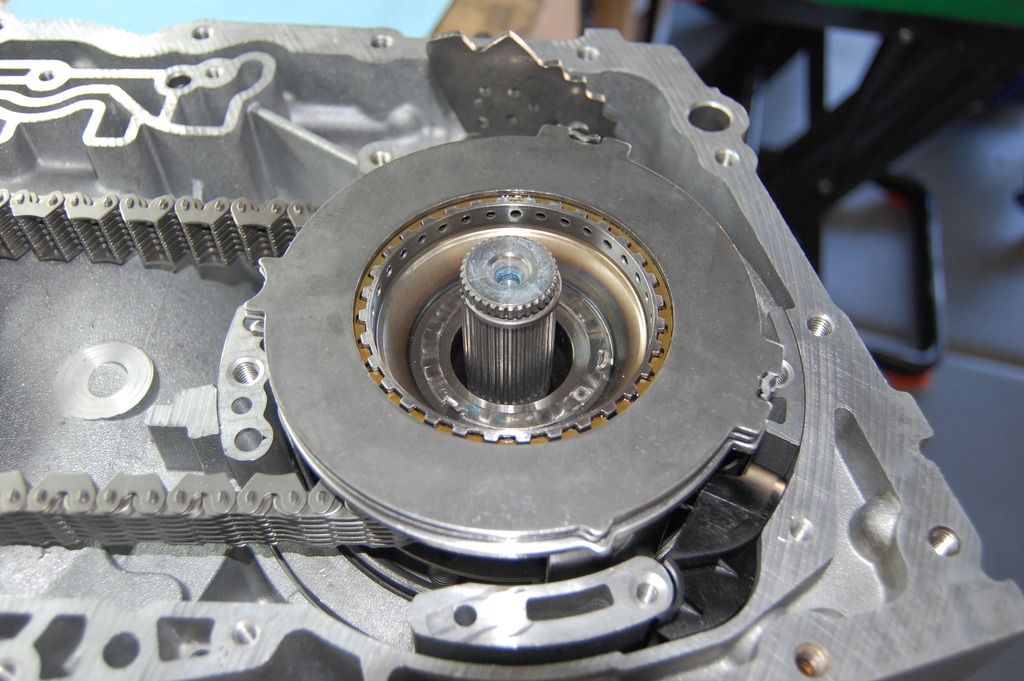

Next the output shaft goes through. A little assembly goo to hold the snap ring on center.

It's in

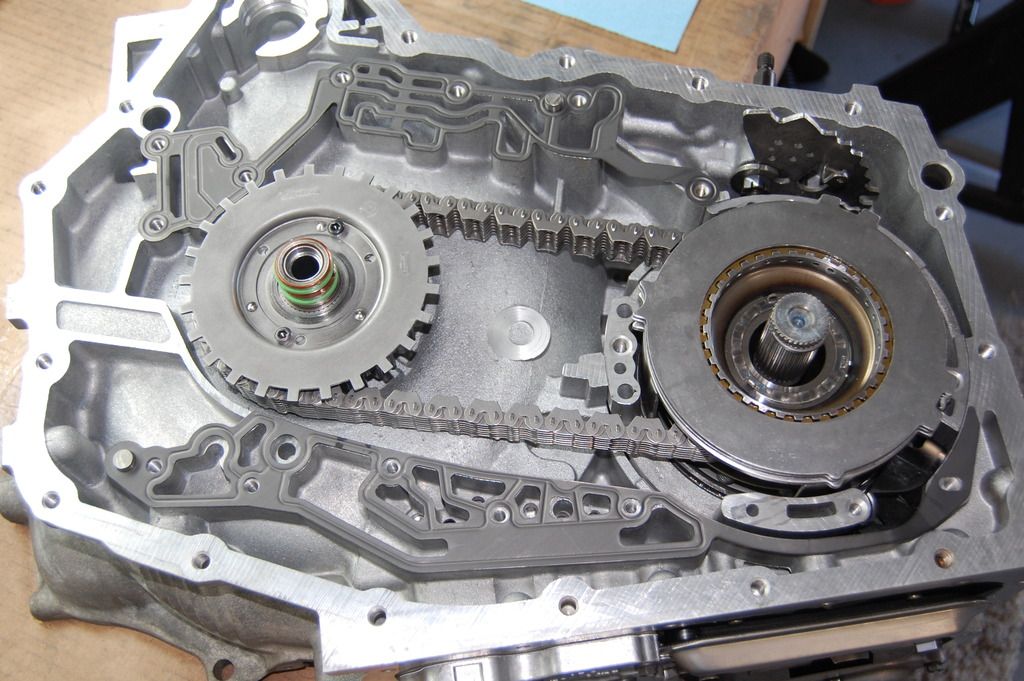

Metal channel plate gaskets on

Channel plate is next. A little goo to keep the thrust washers in place

It's on

Torqued. I hit the heads with a paint marker one at a time to verify each one has been done

It's about at this point when you realize how close to done it is.

It's ok essentially the RB series stuff is Nissan inline 6 engines, they sold some in Australia they are 3 liter engines designed to compete with the 2JZ engine from Toyota (350 GM versus 351 Ford)... Essentially I am just looking for a manual transmission from a mid 90s skyline, the non GTR trans is great to rebuild to hold gobs of power, I am shooting to make mine good for 1000hp, yet only shooting for 800 to the crank.

Now that I understand. Sounds like a blast!

Now back to you, I seriously love reading this thread daily for more beautiful transmission pictures. Very nice indeed man, I do like your methods and how you check everything, never hurts to double check.

Hey, I really appreciate that. My methods go back to my tool and die training. Perfection is the standard. Honestly, part of the reason behind all the pictures is records keeping. It's an easy way to remember exactly what I did. Only takes a couple extra minutes to type up some text and post the pictures. Maybe it will help someone along the way too.

Today was a big day for parts. Things happened at work so I was able to get to the trans shop a day early. 1-2 shift valve, 4th hub, and my super special snap ring showed up!

Price ended up being under $6, so I took it, even though I won't need it on this build. I honestly don't know what makes this snap ring special. The only thing I can think is maybe it's thicker than normal? I don't have another to compare it to. Someone willing to measure one they have sitting around? This one measures 0.077". Give or take...

Fresh valve and solenoid vs old scarred one

And it comes with instructions. Not sure why. If you're this far into a trans, shouldn't you have a manual on hand?

With that, the valve body is finally complete. Waiting for final assembly

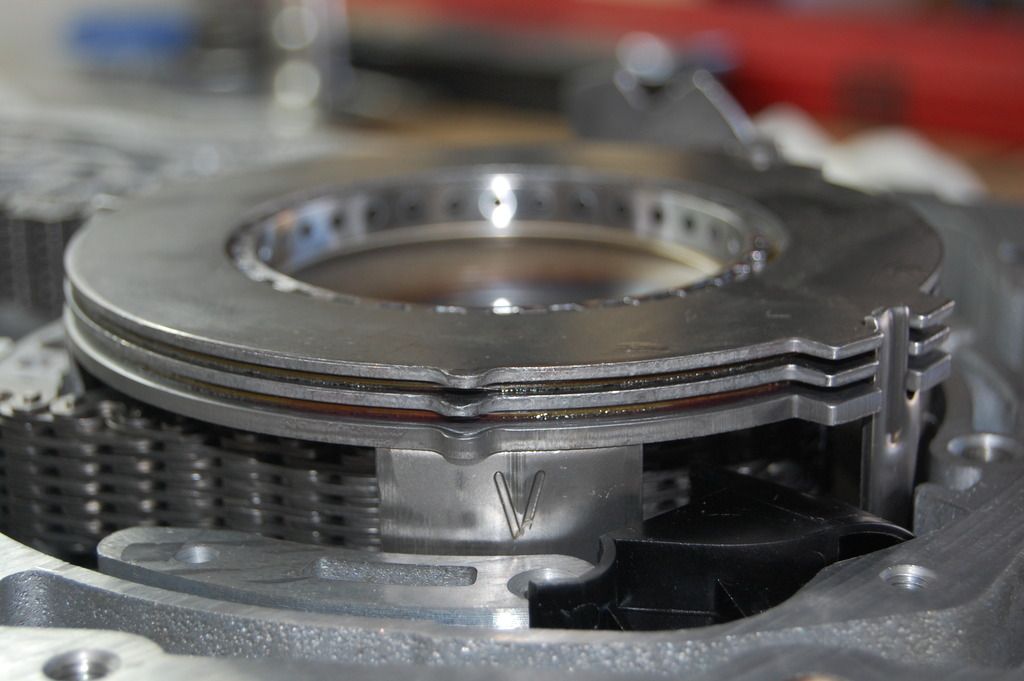

Next step was the 4th hub. Didn't want to go all the way down. It's not uncommon for pressed bushings to close up a bit. You can see where the land on the hub shaft was rubbing hard

Hit the shiny spots with some 600 grit. Took a couple times, but eventually it dropped in.

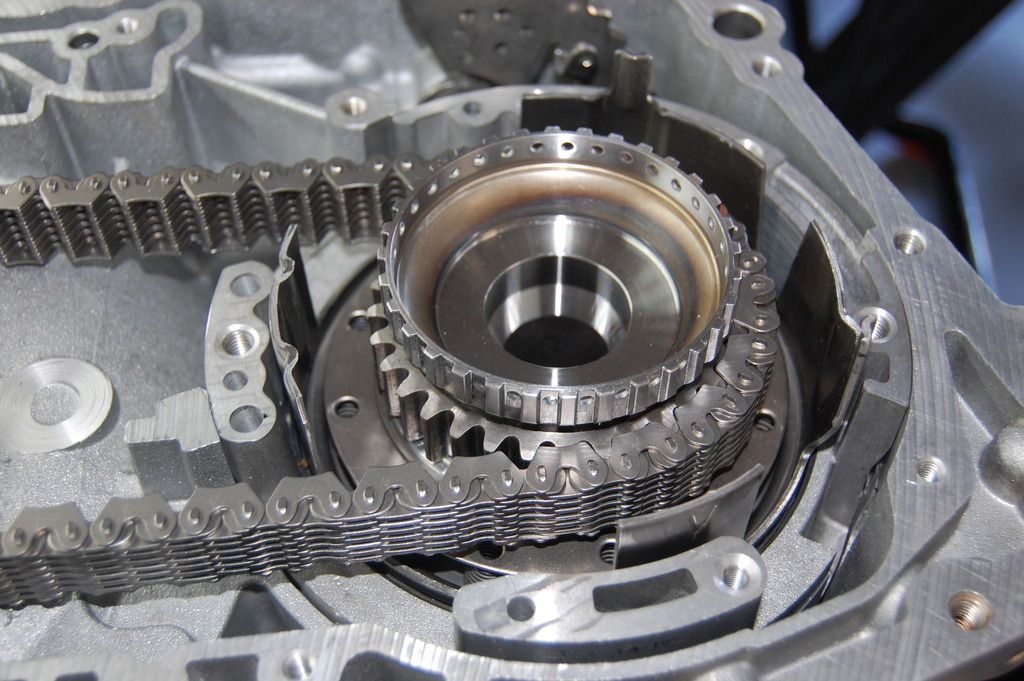

4th stackup

Next the output shaft goes through. A little assembly goo to hold the snap ring on center.

It's in

Metal channel plate gaskets on

Channel plate is next. A little goo to keep the thrust washers in place

It's on

Torqued. I hit the heads with a paint marker one at a time to verify each one has been done

It's about at this point when you realize how close to done it is.

Last edited:

GMR Badass

New member

Re: Built 4t65e - Quality takes time

Hit all of the bolts holding the channel plate to case multiple times. With the revised metal gaskets they crush as you make your rounds in tightening and by the time you're done the first few bolts become out of torque spec.......leads to fluid loss. With the original gaskets it's not an issue but with the revised ones I go over it multiple times.

Hit all of the bolts holding the channel plate to case multiple times. With the revised metal gaskets they crush as you make your rounds in tightening and by the time you're done the first few bolts become out of torque spec.......leads to fluid loss. With the original gaskets it's not an issue but with the revised ones I go over it multiple times.

Turbocharged400sbc

New member

Re: Built 4t65e - Quality takes time

you missed one

j/k

you missed one

j/k

BillBoost37

New member

Re: Built 4t65e - Quality takes time

Are you enlarging the feed holes on the spacer plate?

Are you enlarging the feed holes on the spacer plate?

BrandonHall10

Solving problems

Re: Built 4t65e - Quality takes time

I was not aware of that. Thanks. I will hit them again tonight before the VB goes on.

:th_wavefinger: Don't make me second guess myself. LOL!

You're getting ahead of me Bill. Separator plate mods are on tonight's agenda :th_eyebrows:

Hit all of the bolts holding the channel plate to case multiple times. With the revised metal gaskets they crush as you make your rounds in tightening and by the time you're done the first few bolts become out of torque spec.......leads to fluid loss. With the original gaskets it's not an issue but with the revised ones I go over it multiple times.

I was not aware of that. Thanks. I will hit them again tonight before the VB goes on.

you missed one

j/k

:th_wavefinger: Don't make me second guess myself. LOL!

Are you enlarging the feed holes on the spacer plate?

You're getting ahead of me Bill. Separator plate mods are on tonight's agenda :th_eyebrows:

BrandonHall10

Solving problems

Re: Built 4t65e - Quality takes time

You get what you pay for. You do not want a $50 transmission. :th_shakinghead1:

I'll give $50 to do mine.

You get what you pay for. You do not want a $50 transmission. :th_shakinghead1:

BillBoost37

New member

Re: Built 4t65e - Quality takes time

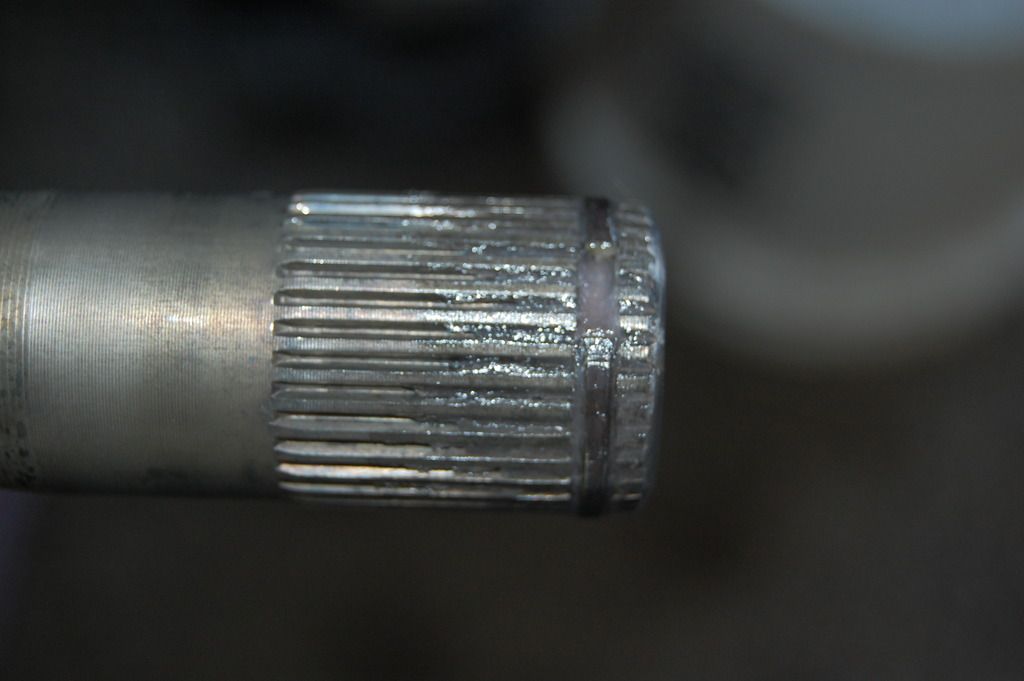

What did you do to my little friend the ISS reluctor?

What did you do to my little friend the ISS reluctor?

keatonregal

New member

Re: Built 4t65e - Quality takes time

Ill take a $51 trans:th_biggrin2:

You get what you pay for. You do not want a $50 transmission. :th_shakinghead1:

Ill take a $51 trans:th_biggrin2:

BrandonHall10

Solving problems

Re: Built 4t65e - Quality takes time

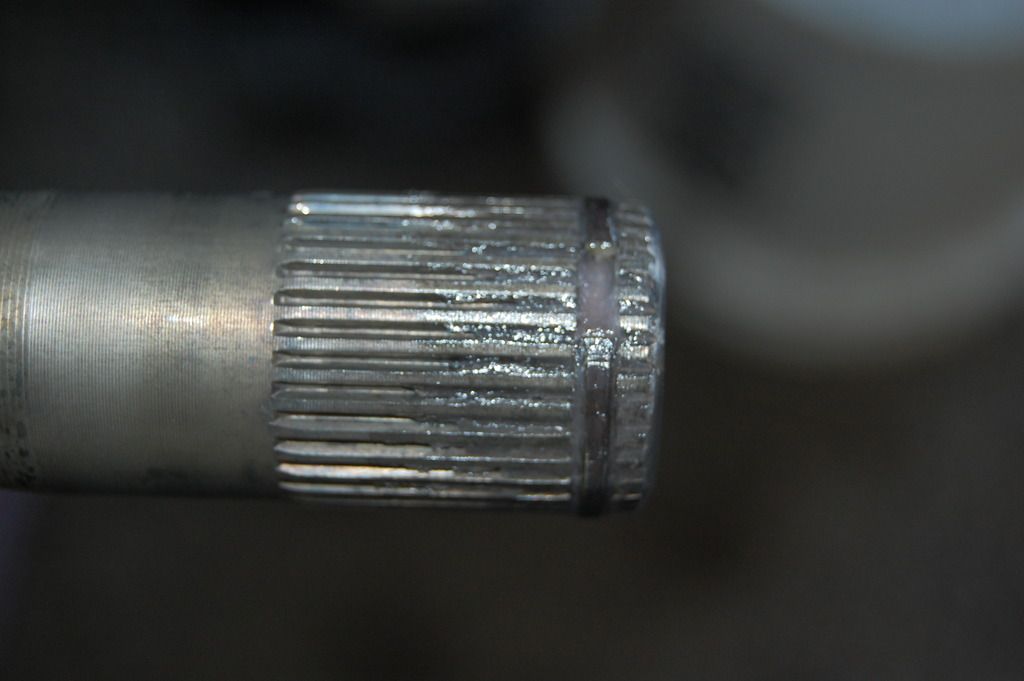

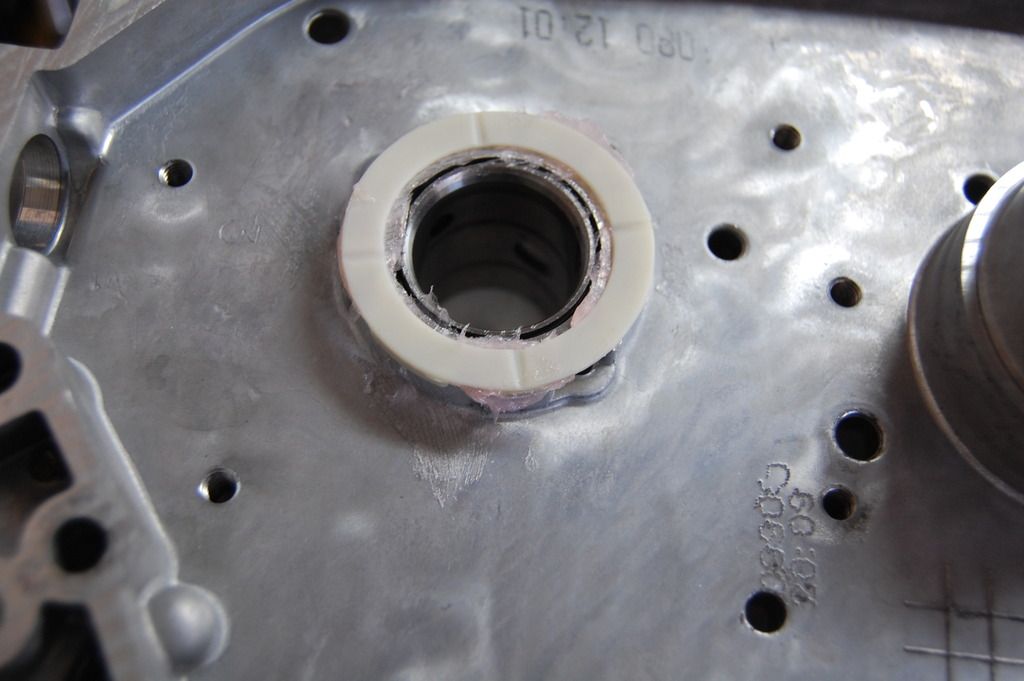

I used a pair of 1/4"-28 button head cap screws. There were 4 existing holes in the driven sprocket that were very close to the 1/4"-28 tap drill diameter, so I went with it. I had to grind some material off the diameter of the heads to clear the boss on the channel plate. Used a drill to spin the screw while grinding. Gives a pretty constant result. When all was said and done, I spun the input shaft in the channel plate to make sure the screws cleared. All good.

Fixed that for ya!

What did you do to my little friend the ISS reluctor?

I used a pair of 1/4"-28 button head cap screws. There were 4 existing holes in the driven sprocket that were very close to the 1/4"-28 tap drill diameter, so I went with it. I had to grind some material off the diameter of the heads to clear the boss on the channel plate. Used a drill to spin the screw while grinding. Gives a pretty constant result. When all was said and done, I spun the input shaft in the channel plate to make sure the screws cleared. All good.

Ill take a $2,510 trans:th_biggrin2:

Fixed that for ya!

keatonregal

New member

Re: Built 4t65e - Quality takes time

Hell, if that's what it takes, id actually take you up on that!

Ill take a $2,510 trans:th_biggrin2:

Hell, if that's what it takes, id actually take you up on that!

BillBoost37

New member

Re: Built 4t65e - Quality takes time

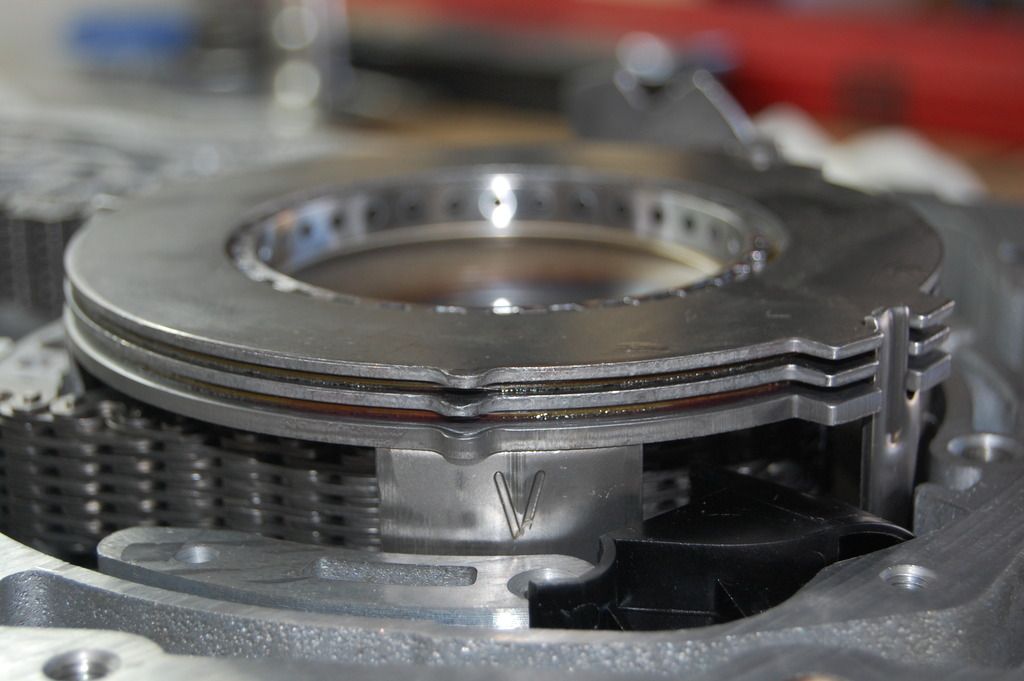

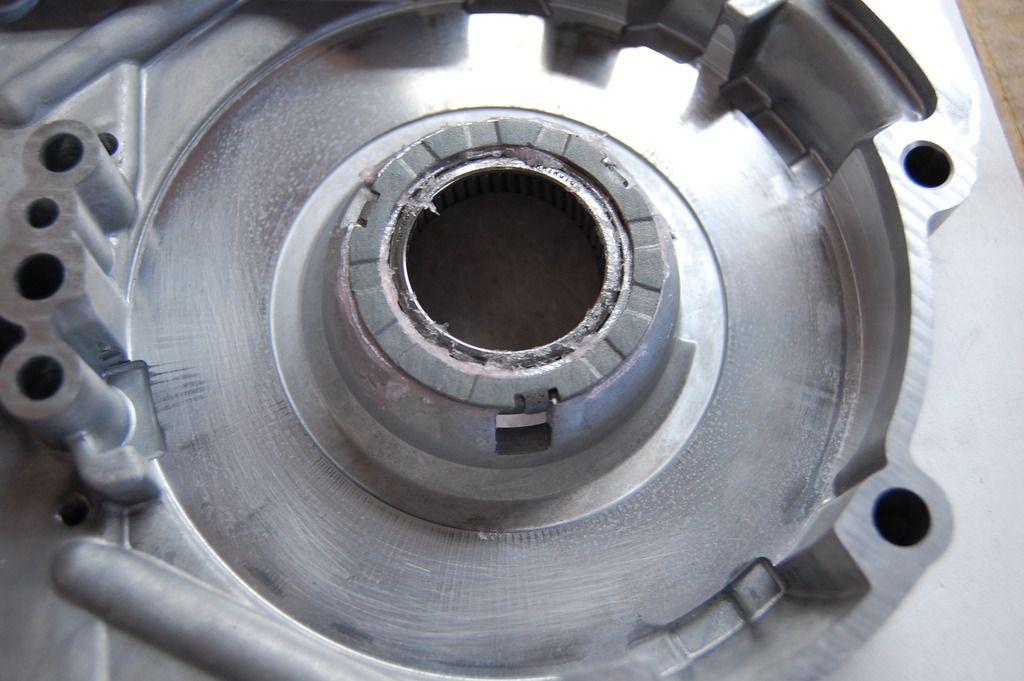

Since we all know I ripped many of those apart, even when that type of screw was used. I have found a few things that have been done to help with the issues.

Here's what happens if your screws back out.

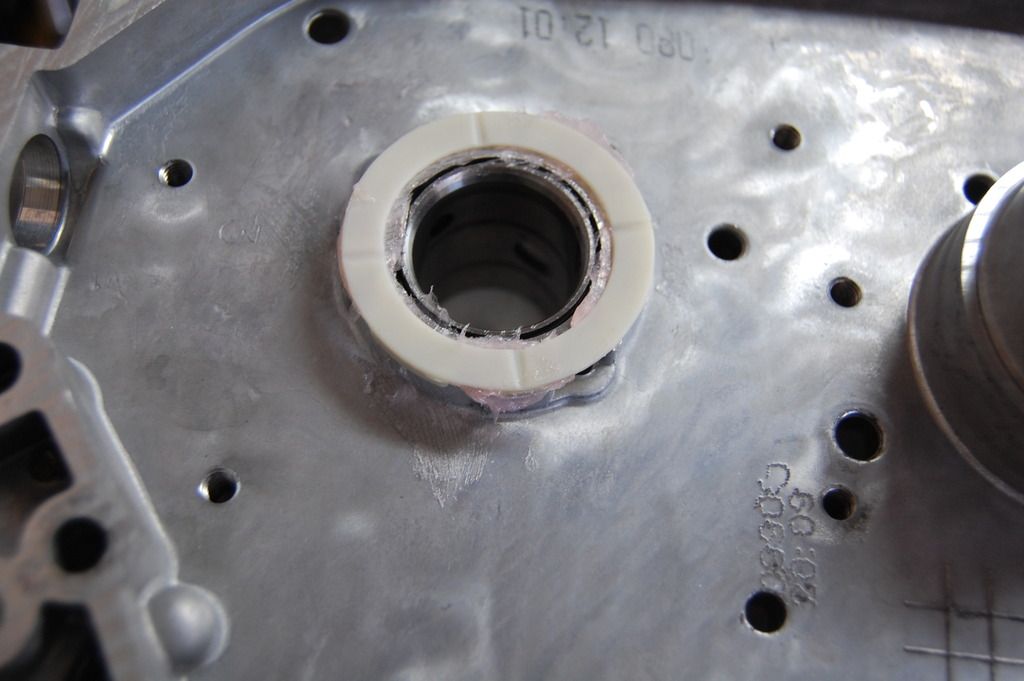

Here's the one I used in the last trans I built for the Regal. You are correct, it was welded to the gear.

The shop that builds for ZZP, welds the tops of the pins so that they can't loosen and allow slop.

And ... this is from a dynotech trans if I recall properly. It's the sungear in the diff

Since we all know I ripped many of those apart, even when that type of screw was used. I have found a few things that have been done to help with the issues.

Here's what happens if your screws back out.

Here's the one I used in the last trans I built for the Regal. You are correct, it was welded to the gear.

The shop that builds for ZZP, welds the tops of the pins so that they can't loosen and allow slop.

And ... this is from a dynotech trans if I recall properly. It's the sungear in the diff

BrandonHall10

Solving problems

Re: Built 4t65e - Quality takes time

Yeah, but we all know you're like a professional transmission killer!

I guess anything's possible, but with Loctite, fine threads and an interference fit, it would take a LOT for those screws to back out. I see what you're saying though.

Are the grooves in the sun gear for lubrication?

Yeah, but we all know you're like a professional transmission killer!

I guess anything's possible, but with Loctite, fine threads and an interference fit, it would take a LOT for those screws to back out. I see what you're saying though.

Are the grooves in the sun gear for lubrication?

BillBoost37

New member

Re: Built 4t65e - Quality takes time

Might help if I told you I tore up 2 setups that were screwed with loctite and I tore up one from TEP where the holes are drilled smaller in the gear. I was evil to the trans and had some power. Most would tell you it wasn't enough power, however ...I pretty much mastered it since I have pics of at least four times that I did it.

I believe so on the sungear.

but with Loctite, fine threads and an interference fit, it would take a LOT for those screws to back out.

Are the grooves in the sun gear for lubrication?

Might help if I told you I tore up 2 setups that were screwed with loctite and I tore up one from TEP where the holes are drilled smaller in the gear. I was evil to the trans and had some power. Most would tell you it wasn't enough power, however ...I pretty much mastered it since I have pics of at least four times that I did it.

I believe so on the sungear.

BrandonHall10

Solving problems

Re: Built 4t65e - Quality takes time

Well, it's not too late. Maybe I'll pull the driving gear out and have someone TIG a tack on each one of those screws. That would guarantee they couldn't back out.

Well, it's not too late. Maybe I'll pull the driving gear out and have someone TIG a tack on each one of those screws. That would guarantee they couldn't back out.