BrandonHall10

Solving problems

Re: Jane's 4t65e - It's tedious

Thanks!

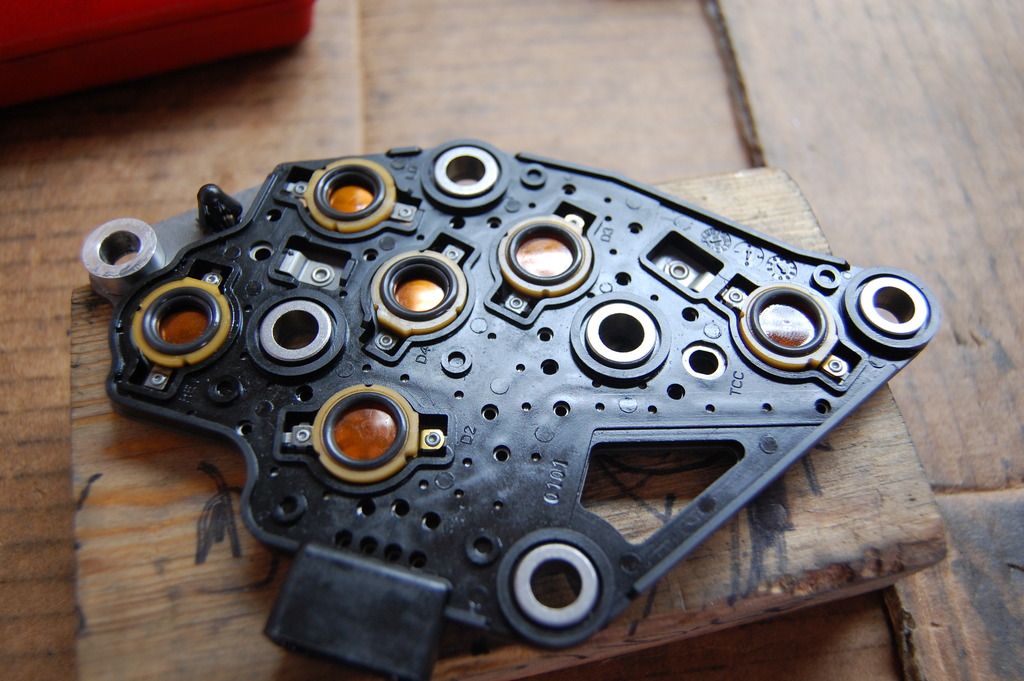

I used your write up when I put the shift kit in my car. (Accumulator only) That was the most complicated thing I'd done up to that point, and having that as a guide was very helpful. Thank you for that!

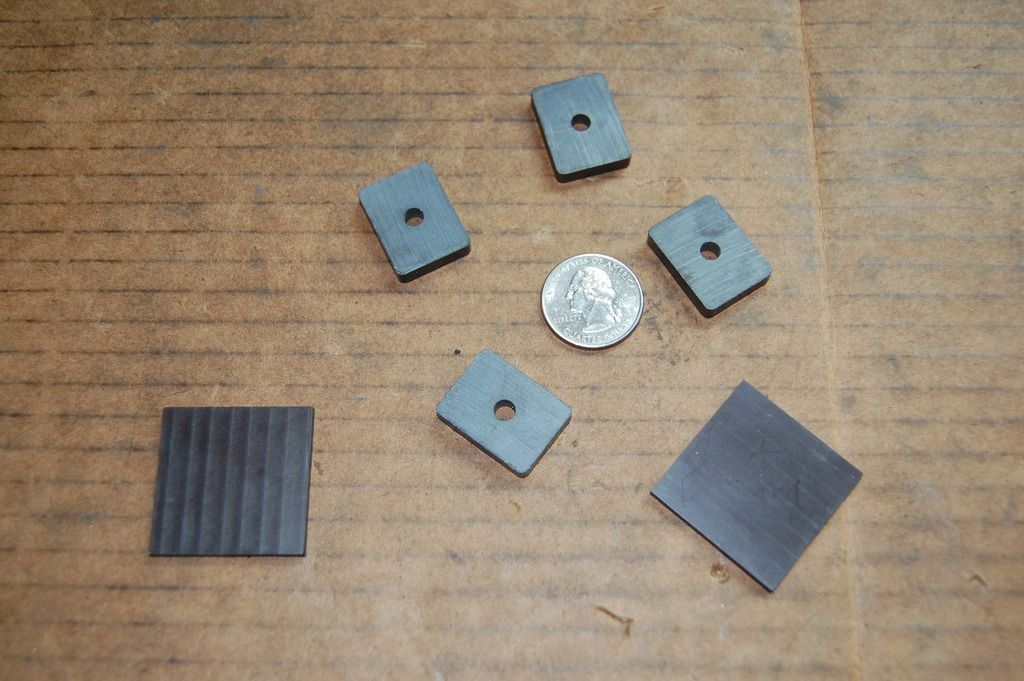

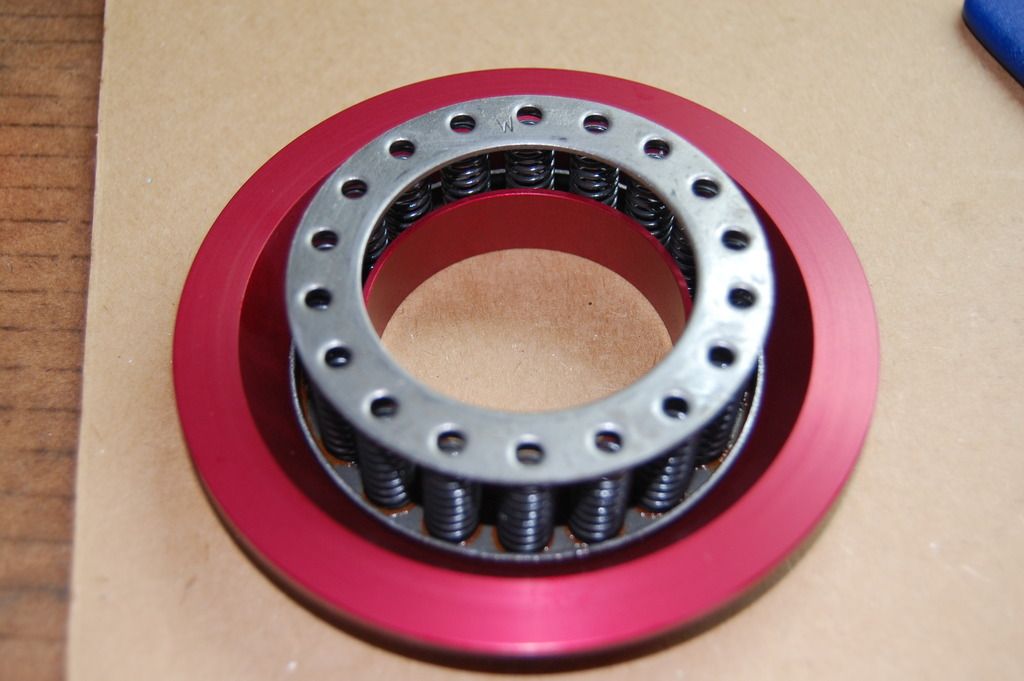

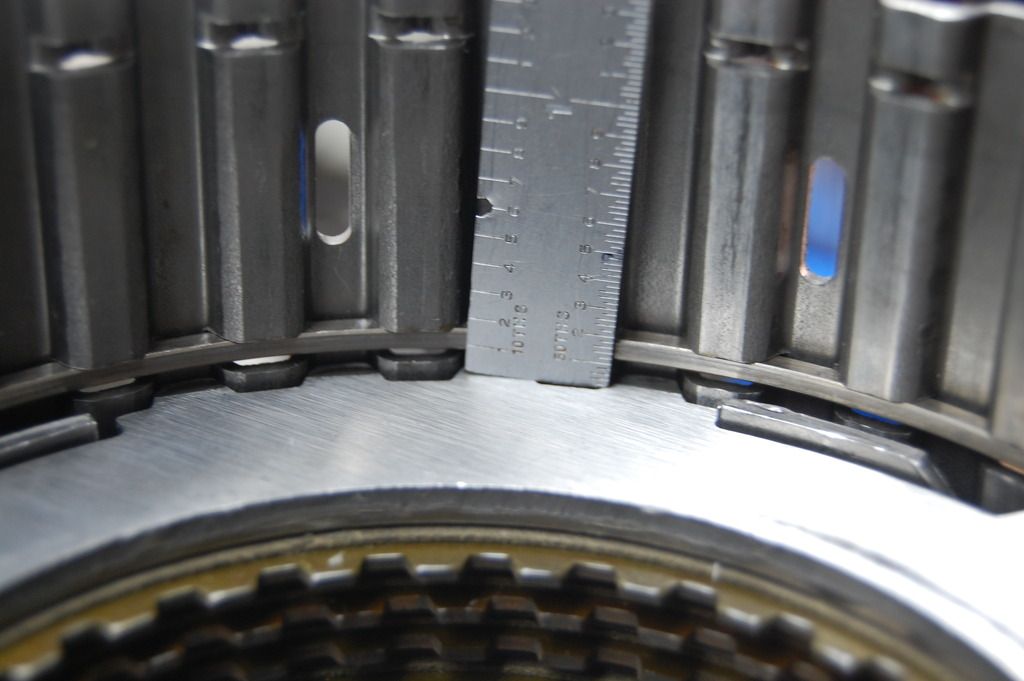

I thought about putting different springs and spacers in, and I still may at some point, but I figured the standard pieces would be a good place to start. Having a pan with a drain plug will make it less painful when I do.

If the '06 is boosted, you'll be in there before you think. Haha!

Thanks!

I used your write up when I put the shift kit in my car. (Accumulator only) That was the most complicated thing I'd done up to that point, and having that as a guide was very helpful. Thank you for that!

I thought about putting different springs and spacers in, and I still may at some point, but I figured the standard pieces would be a good place to start. Having a pan with a drain plug will make it less painful when I do.

If the '06 is boosted, you'll be in there before you think. Haha!