Re: Built 4t65e - Quality takes time

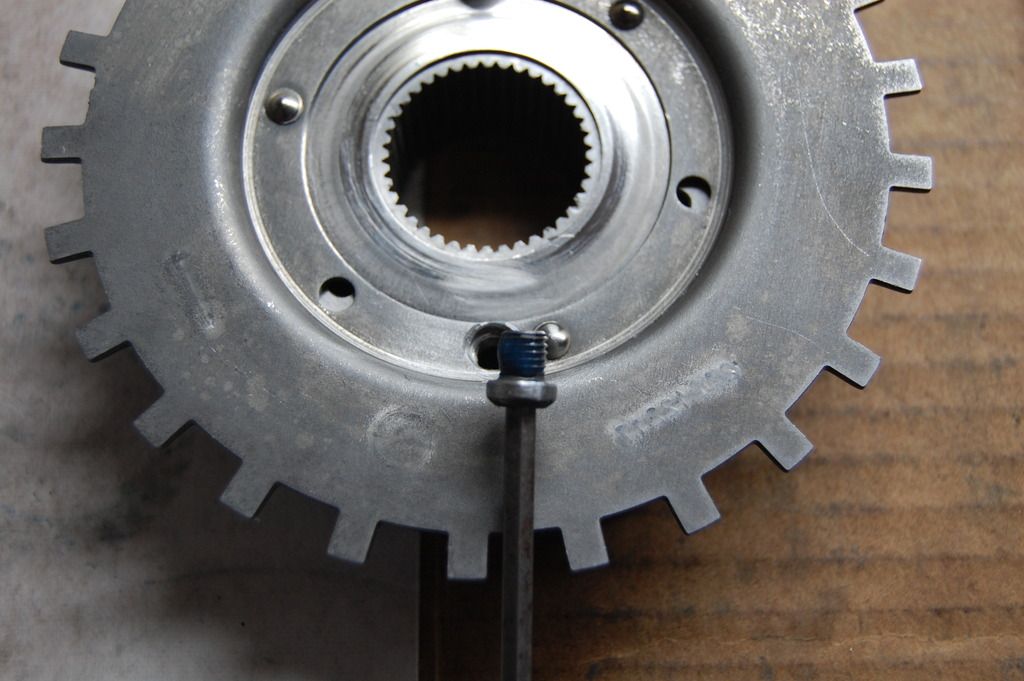

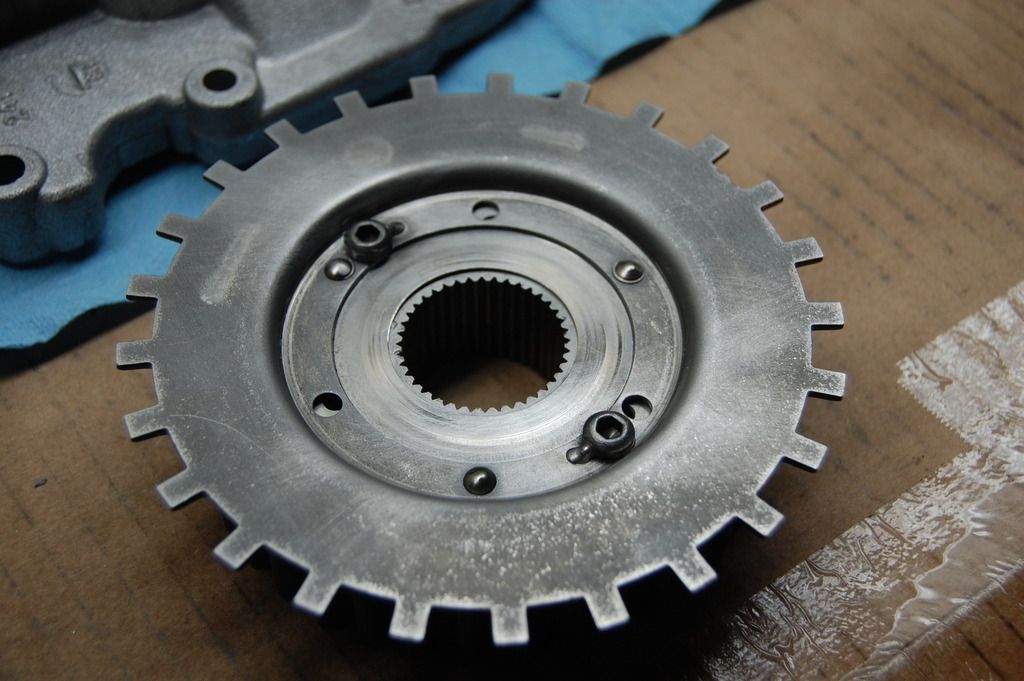

Well, Bill mentioned welding the reluctor. Now I have to do it. Found a guy on craigslist that can do it tomorrow. We'll see how that goes...

I'm taking a little different approach though. By tacking the screw heads, that will keep them from backing out. If, for some reason I ever need to separate the reluctor from the sprocket, I'll just cut the weld and back the screw out. Or drill the screw head off. Either way, the sprocket remains un touched.

Two steps forward, one back. Had to excavate the sprocket

While prepping for the weld, I noticed one of the screws was just a hair too long. Ground it down then threw it in my hillbilly lathe to chamfer the thread

A little loctite cause, why not?

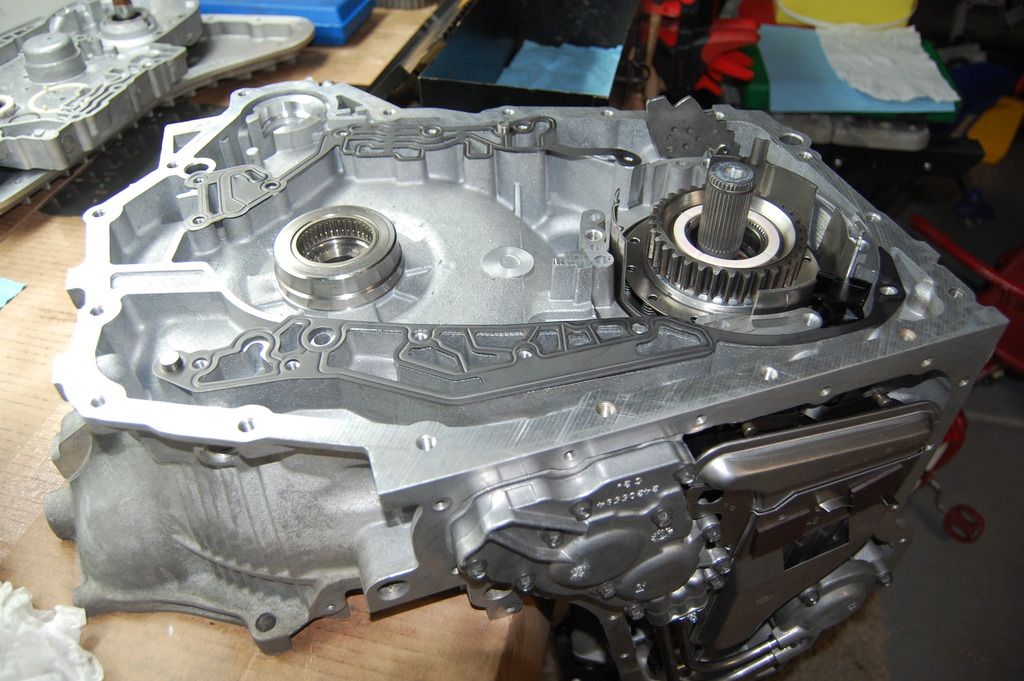

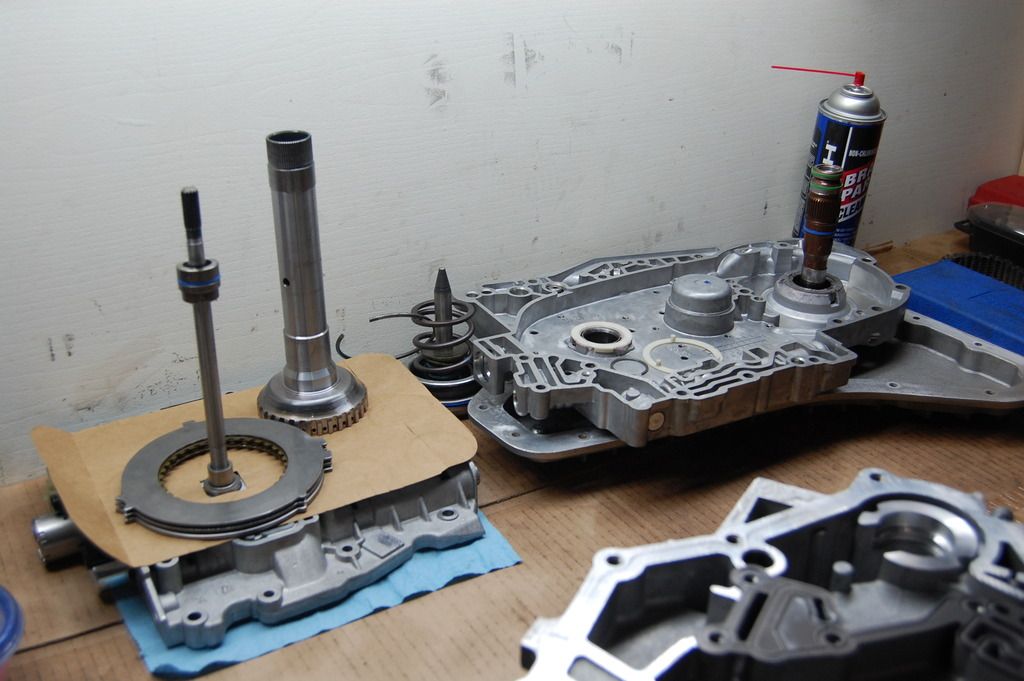

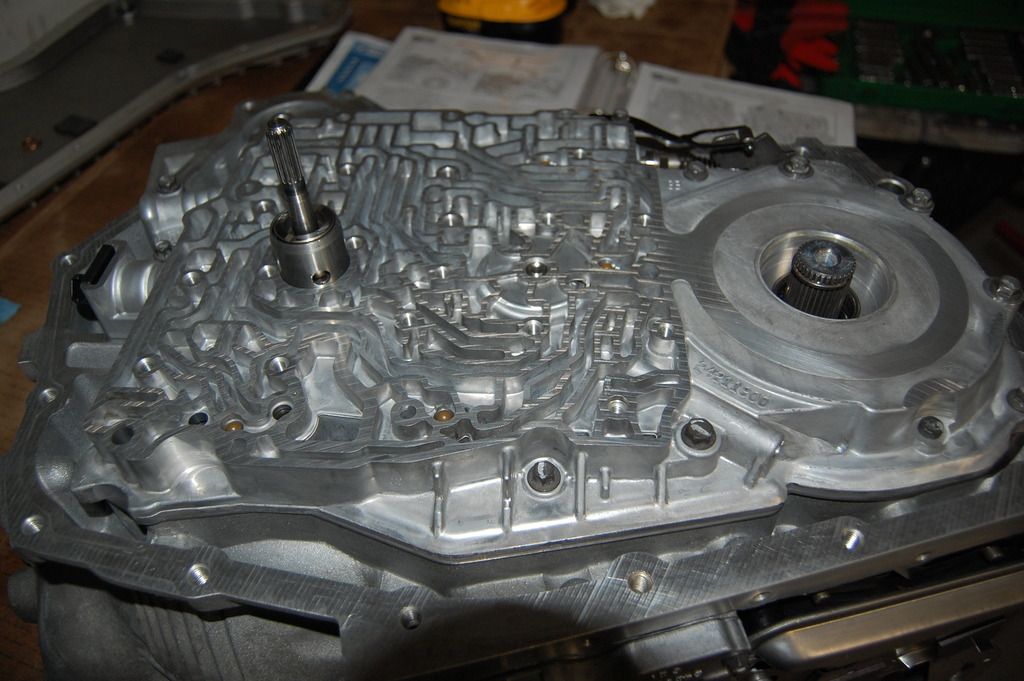

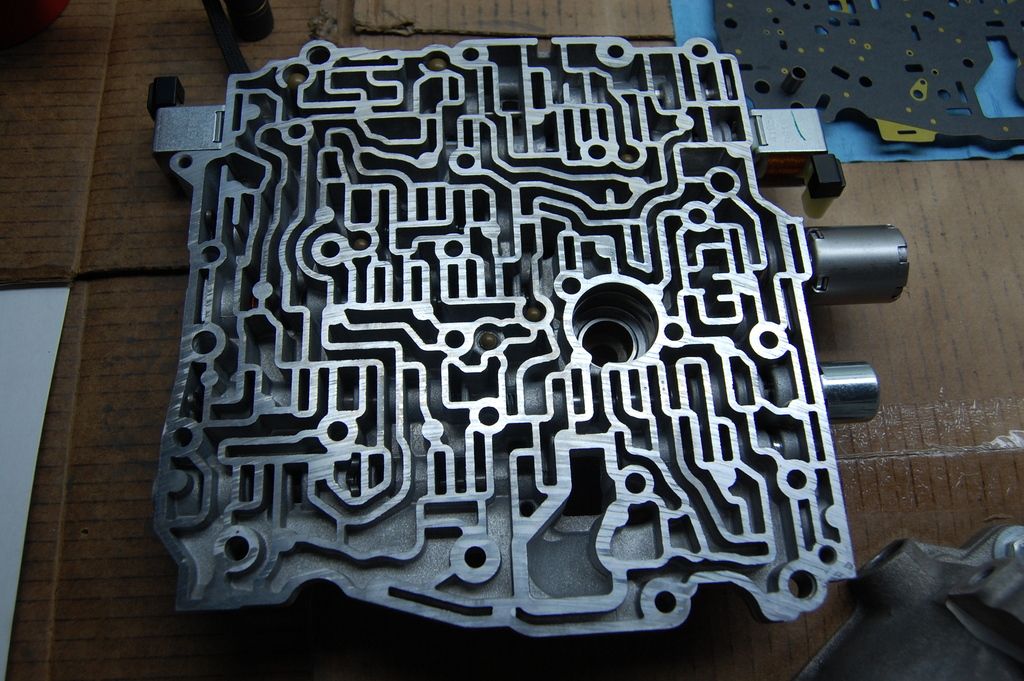

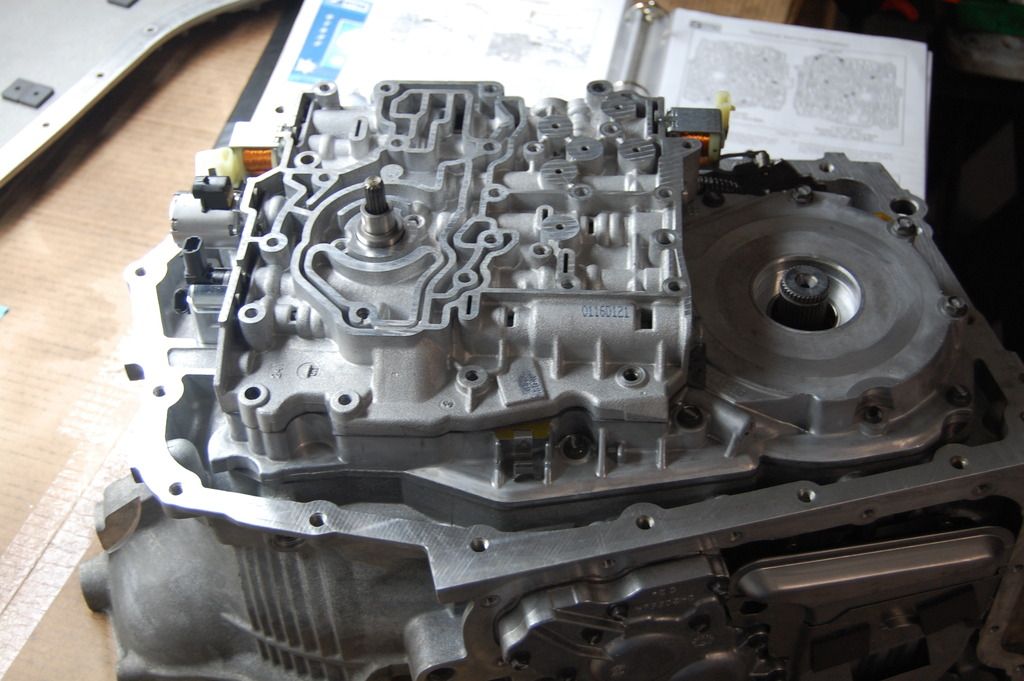

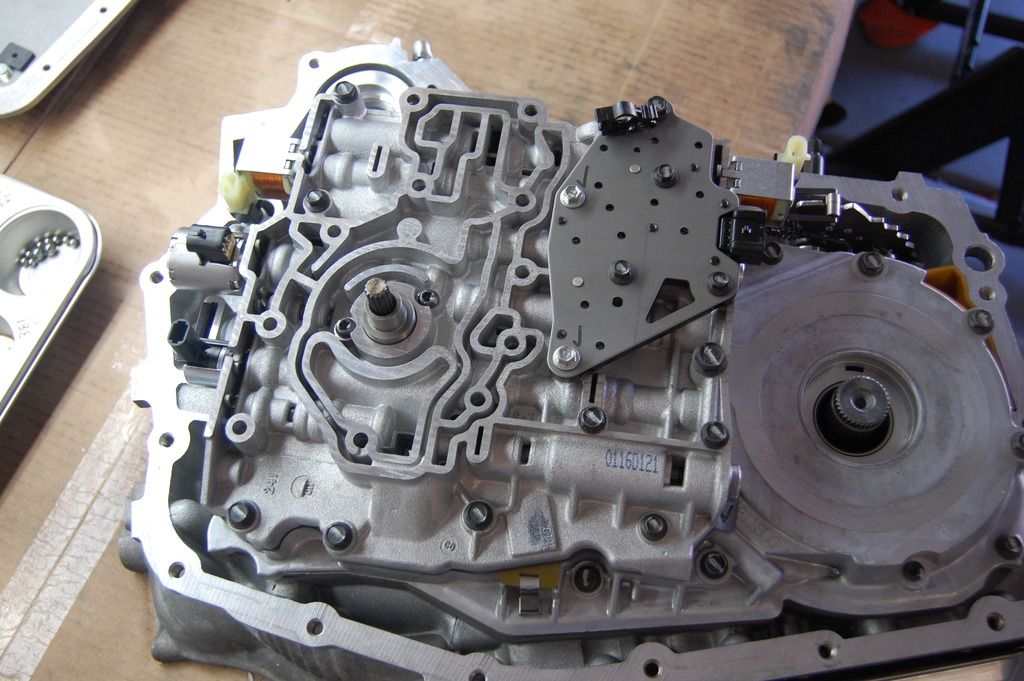

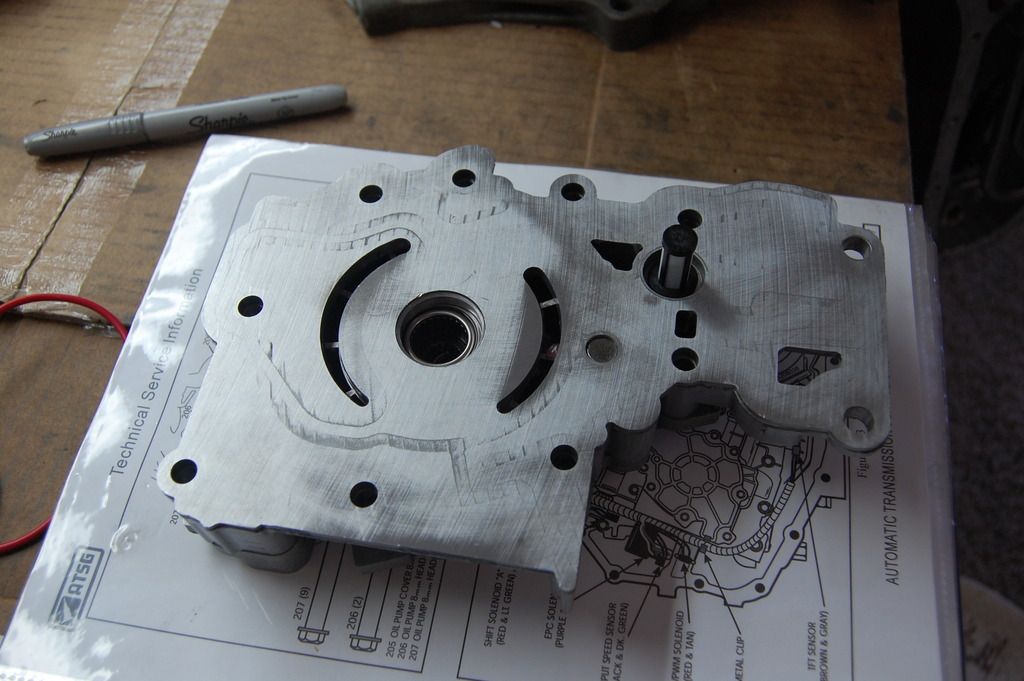

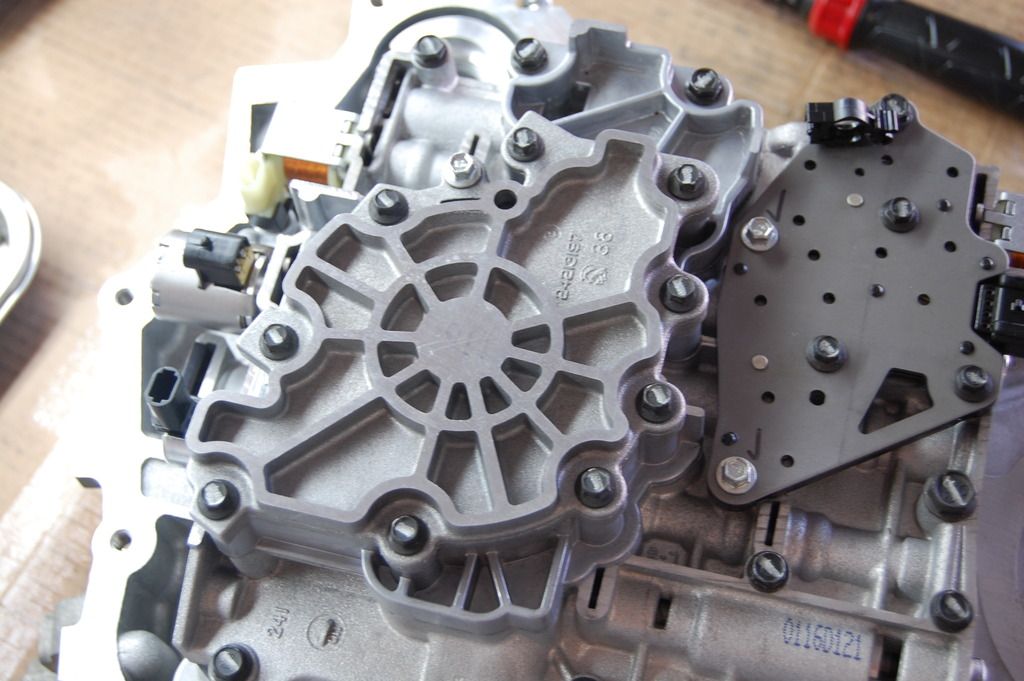

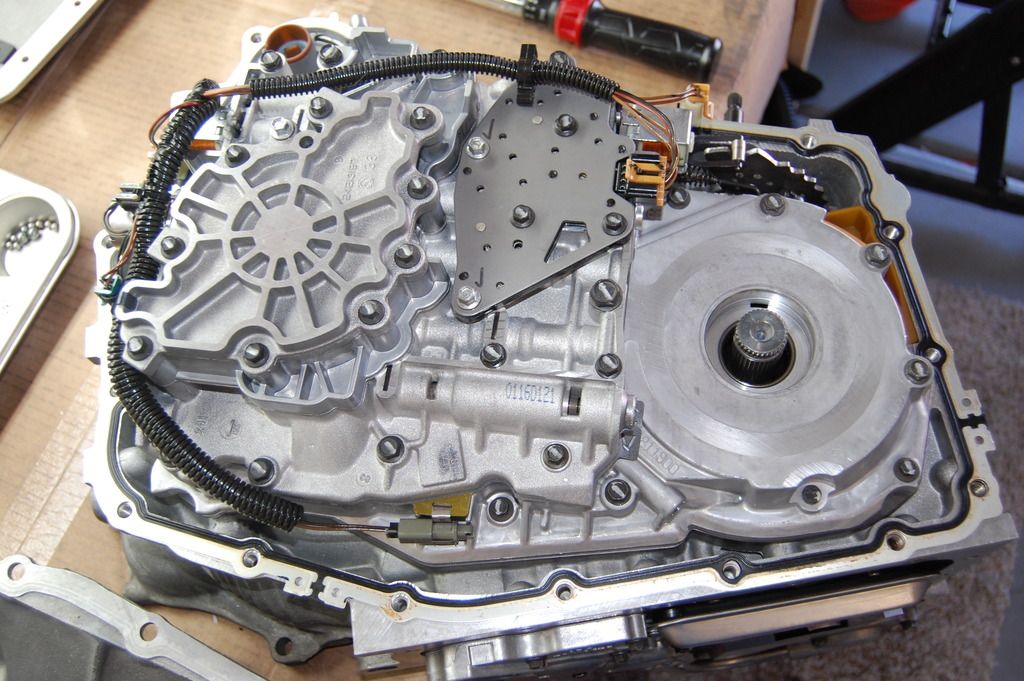

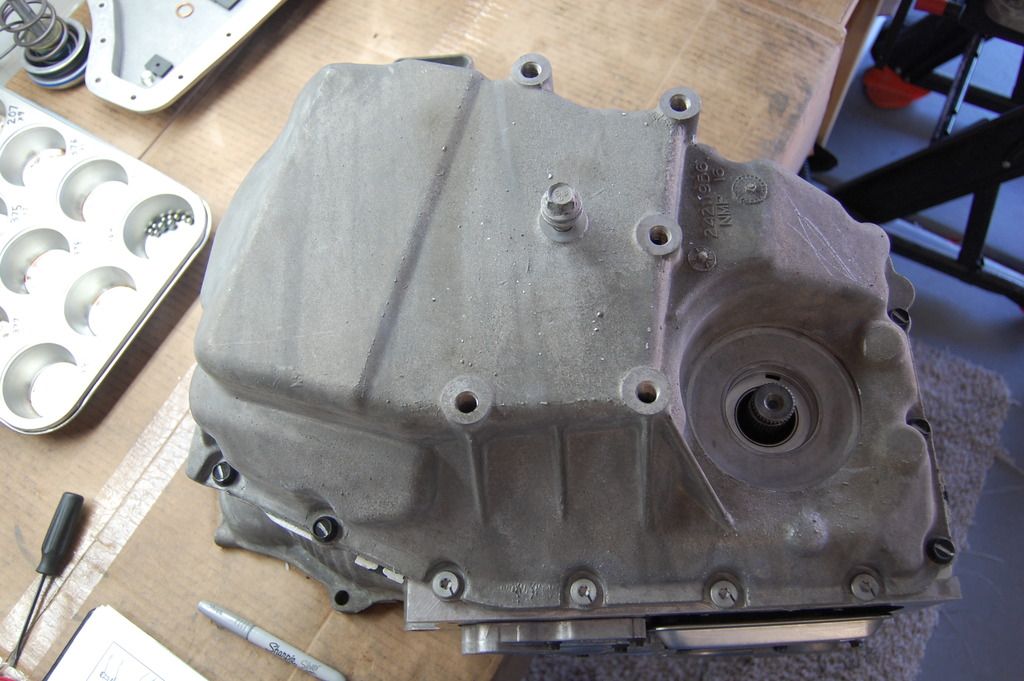

That's about all I can do until I get the welded sprocket back, so I just started taking pictures....

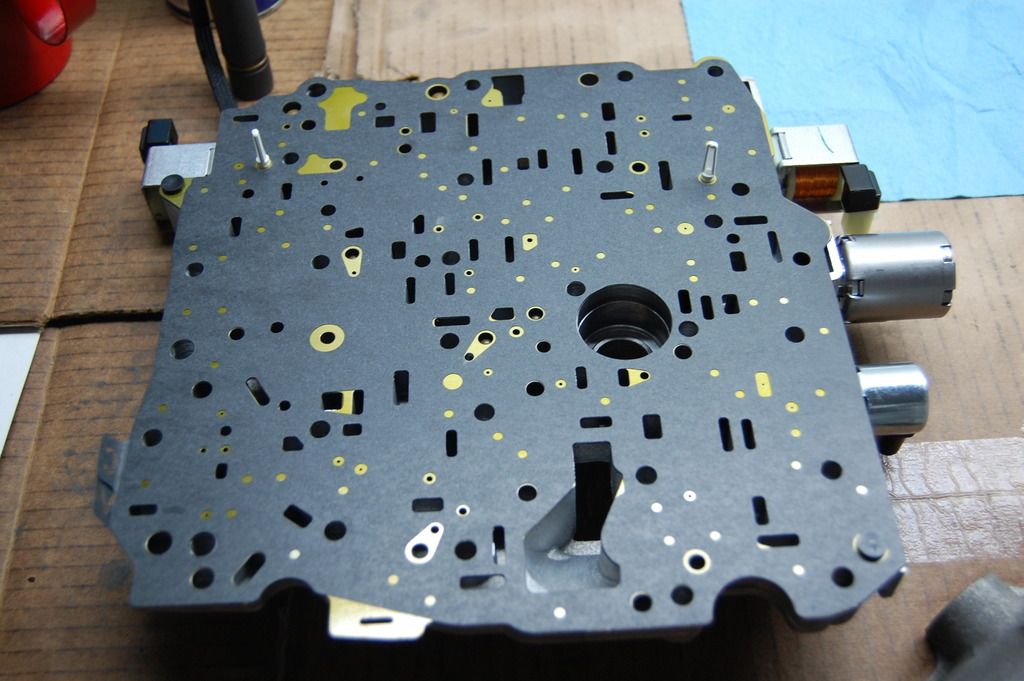

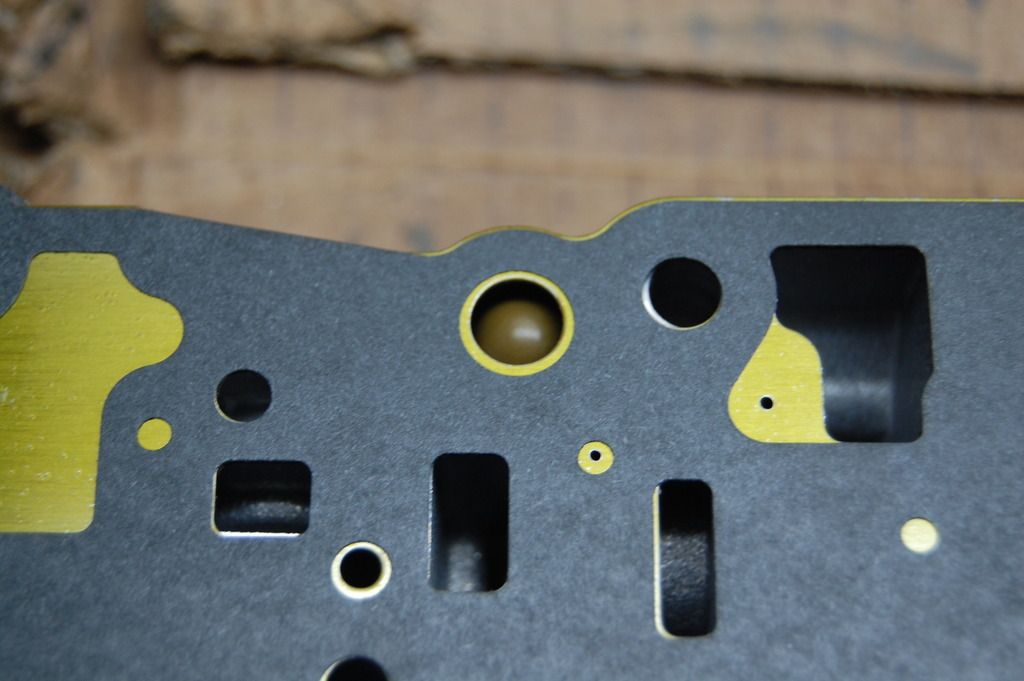

My upgraded balls

Newly acquired tools. Thanks Billboost :th_thumbsup-wink:

It's a terrible thing when you outgrow a toolbox. The black one used to hold all my transmission specific tools

Not anymore

Remember me saying I wasn't the one who tore this down? Here's what happens when you go after #435 unprepared. I managed to extricate them without too much trouble though

And just so I don't forget why I'm doing all this