Booba5185

New member

Great tip, I'll be headed down to my hardware store to look for those. I've been following along with this thread, minus the TCC PWM solenoid since that was already done. http://www.grandprixforums.net/thre...TCC-4th-Clutch-Hub-Replacement-in-the-Vehicle

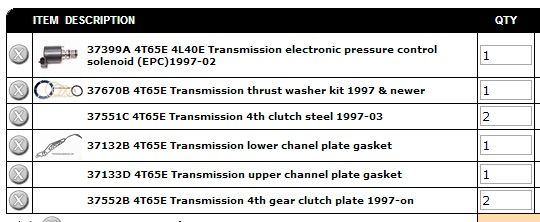

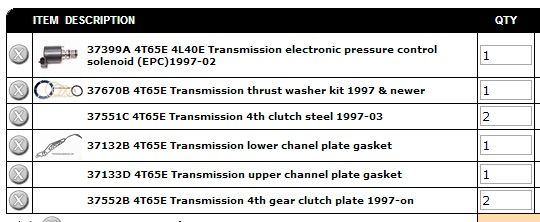

So short of the shaft itself, vasoline (I have it already), fluid, and the headless bolts, this should do it, right?

So short of the shaft itself, vasoline (I have it already), fluid, and the headless bolts, this should do it, right?