you just dont want the valves floating on you. springs help with that. but stronger springs also beat on the timing chain, so you need to deal with a double roller and all it take to make that work right too.

some guys are up to 7,000 rpm, thats like so silly to me, but every cam has its power range.

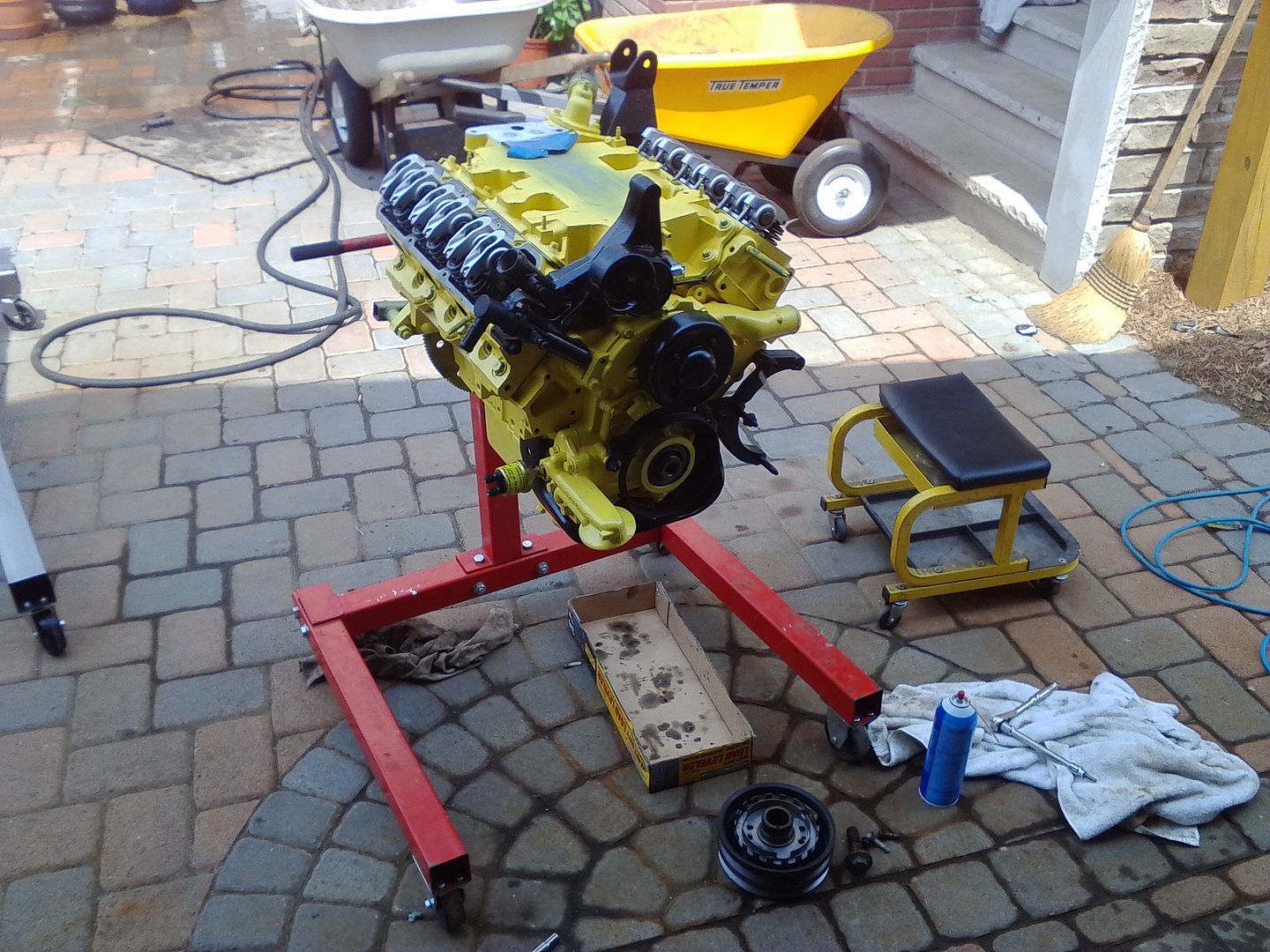

as far as the rebuild, the machine shop is a great first step, it needs that. id have them cut/grind/polish the crank, balance the rods. after all that the rebuild is standard. thing is the blocks twist when the crank comes out, so getting the mains align honed is the most important part of the rebuild. as well as making damn sure all your clearances are with in spec on the bearings. ( but it seems you know all that stuff already)

and a good old hot tanking of the block cant hurt either, make sure its super cleaned out.

sad part is even after all this they some times dont last 2 miles. just had a guy here who had the shop rebuild his bottom end, and it spun a bearing asap.

then we also have guys who rebuilt motors that have lasted 30,000 miles and still run great. rebuilding is a expense crap shoot in my book.

why we like to use a 3 to 400 used black to start with, then build it up from there. any engine with around a 100,000 miles is a baby still lol

like my set up now, i have a regal gs, the sc engine blew up, and i used a l36 bottom end, some lightly ported l67 heads, 1.95 roller rockers and the stock pulley back on. its pulling almost as hard as the the old 3.4 pulley on the old l67. cost about 200 in gaskets and fluids and done.

my old engine had 240 on it, this one has 109,000 and purrs like a kitty.