goldgp

Grocery Getter x2

Hello all! Now before you get too excited, lets get this out of the way... This is not a big bad Getrag 284 swap, think of this as more of an experiment of longevity

This swap is with the weaker little sister of the 284, the 282, found in fieros, cavaliers, sunfires, older grand prixs, low torque stuff like that. I may be wrong here, but i believe the rated torque on the 282 is right at 200 ftlbs MAX. So heres my thought process. I wanted to go manual with my GTP, not because of any issues with my auto tranny, i just decided it would make it a more enjoyable experience to drive. I knew that i did not want the headache of A: Finding a unicorn 284 in good condition, and B: not being able to ever rebuild it or get any parts. Also, damn that clutch cost alot for the 284!:th_thumb-down: Now, my mods are in my signature for my GTP, i knew going into this that the chances of nuking this thing the first pull were really good. Im not breaking the sound barrier performance wise, but i knew with a cam and 3.4 gen v the odds were against the 282. This thread will be continuously updated as to issues and mileage of the swap, to kinda see if this is a viable swap for people that have lower power builds. As i type this 9/14/17, i have 12400 miles on the build, roughly 500 of those are easy miles for clutch break in, the rest are not easy. So far this swap has done great, no issues, super fun, and is taking my beatings. This wont be a super detailed thread yet, but i will edit and add too it.

As a note before all the pics, If you ever plan to go turbo of do a max effort blower build, this is not the tranny for you, dont even bother.

So, this is the donor car. Shes an 89 grand prix coupe, rode hard, put away wet.

And heres the recipient of the swap, my 98 GTP.

See ya later you boring bastard

The teardown starts

4 speeds taking a vacation untill it goes in my 2000

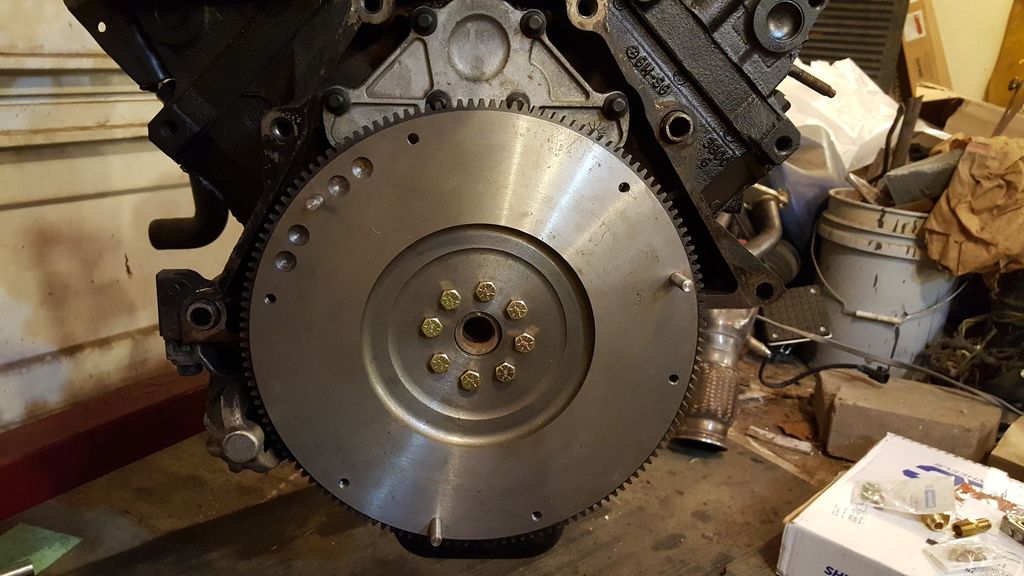

The dirty 282 temporarily mated to my motor ( my gf photobombed my pic with her upper intake she just painted for her turbo 90 foxbody)

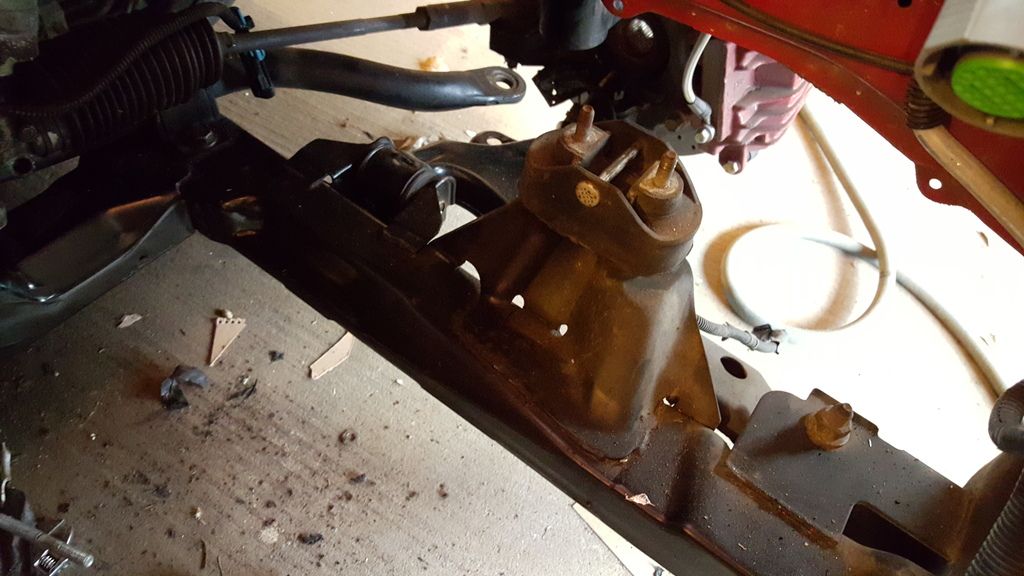

So after getting the motor out, i started on the interior, which is the hardest part of the swap.

Then the dash comes out

Just so we can get to the pedal box

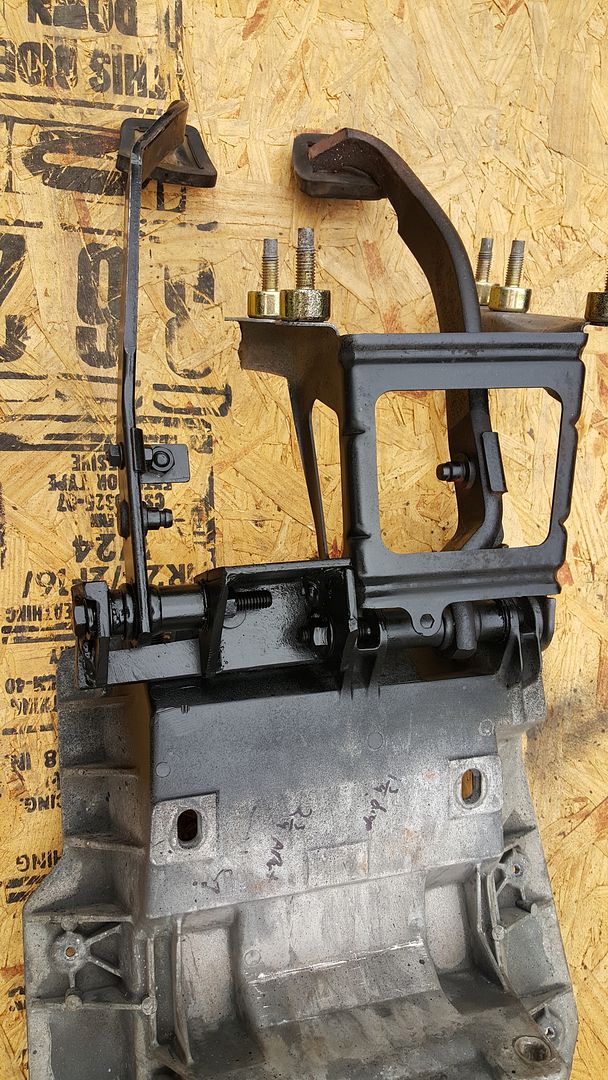

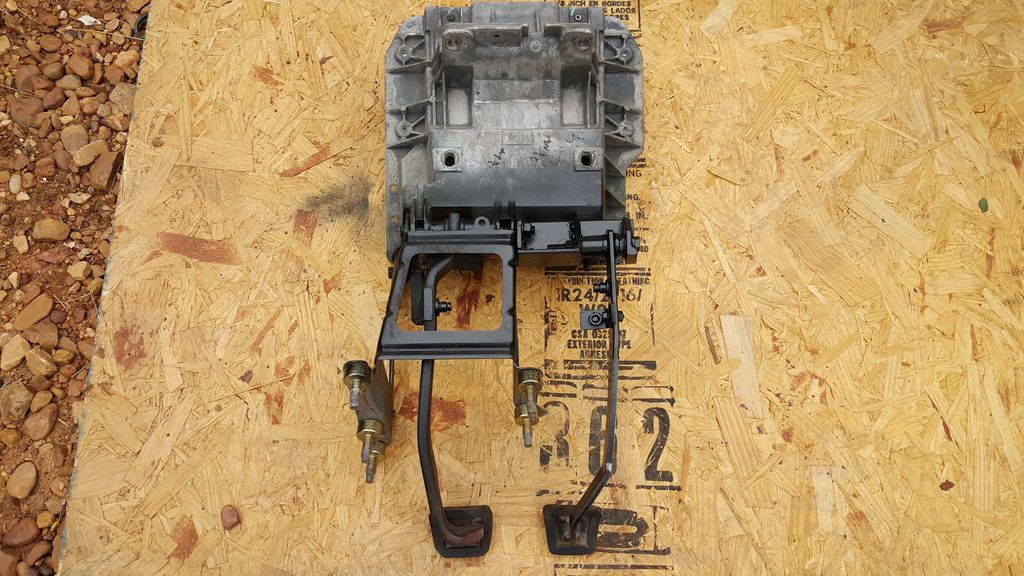

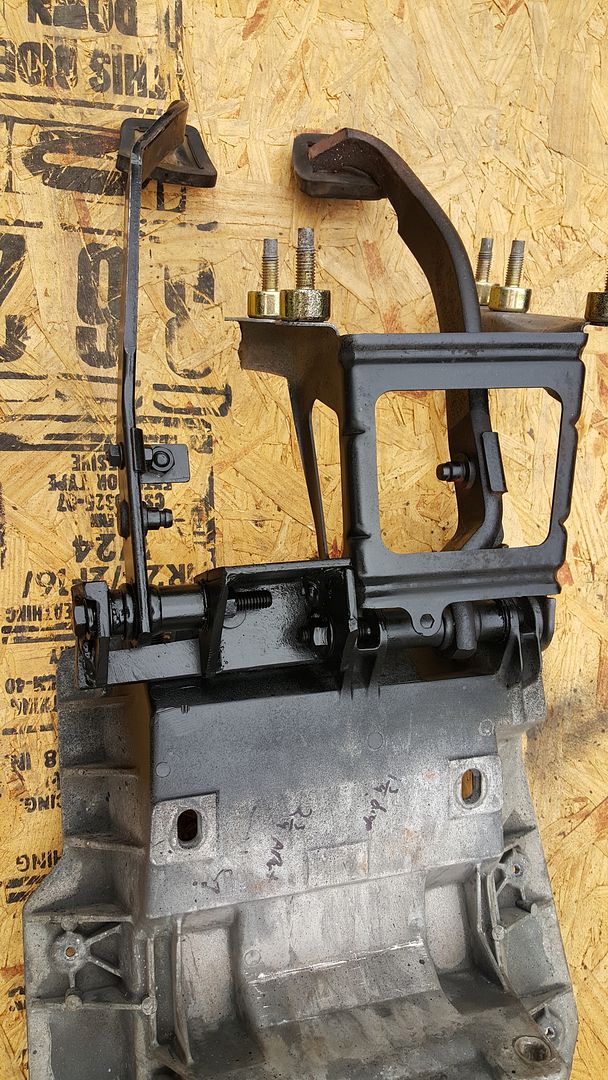

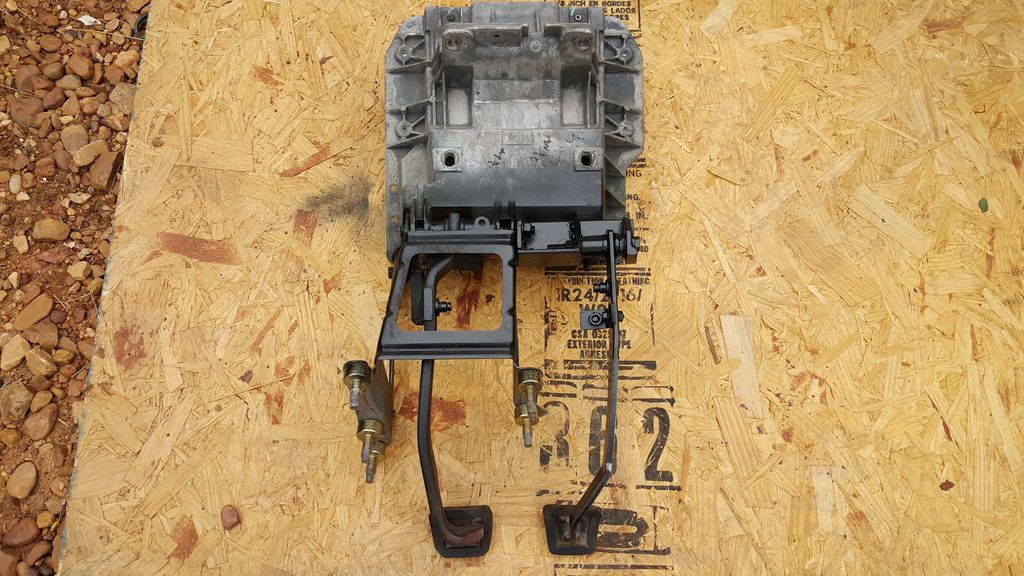

89 pedal box on the left, 98 on the right. And no, the 89 box will not just bolt in, wish it would.

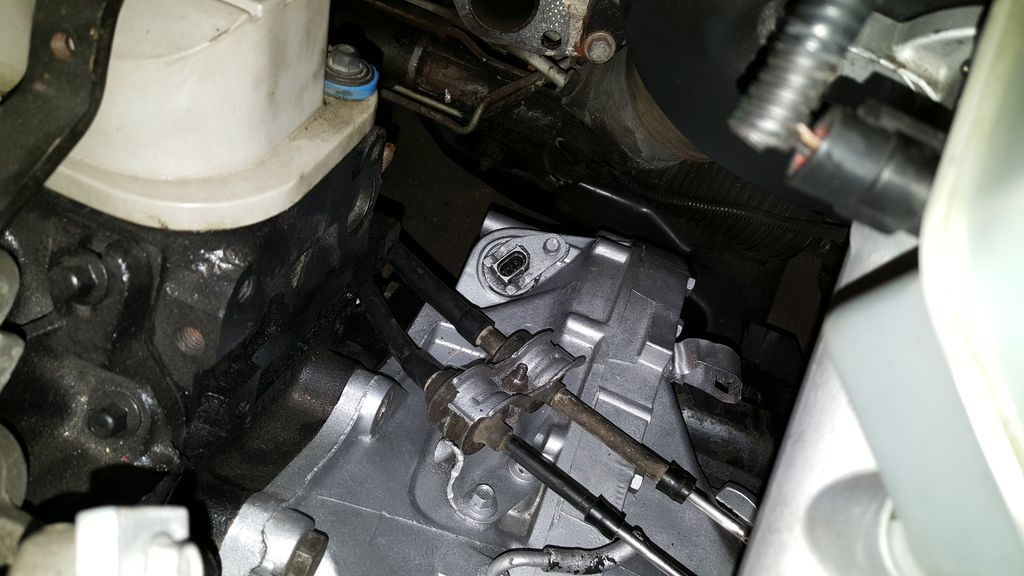

Now for me, adding the clutch pedal to the 98 pedal box was the hardest part of the swap, I just used the measurements off the old box , and started copying that with a piece of angle. Its crude, but i dont fabricate often. lol

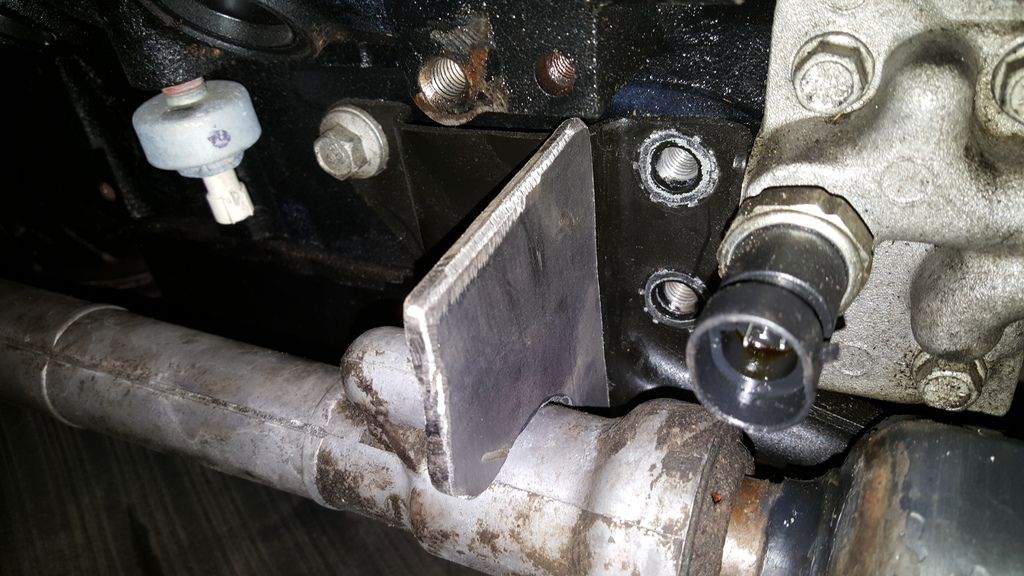

Here is the general idea, just making the pivot point with the angle. It gets a little prettier as it progresses, but not much.

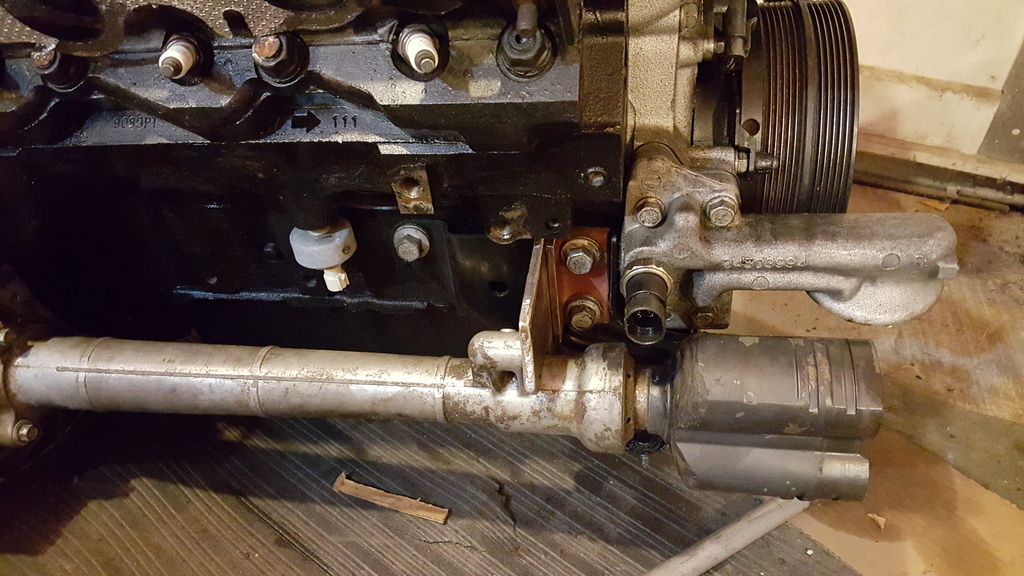

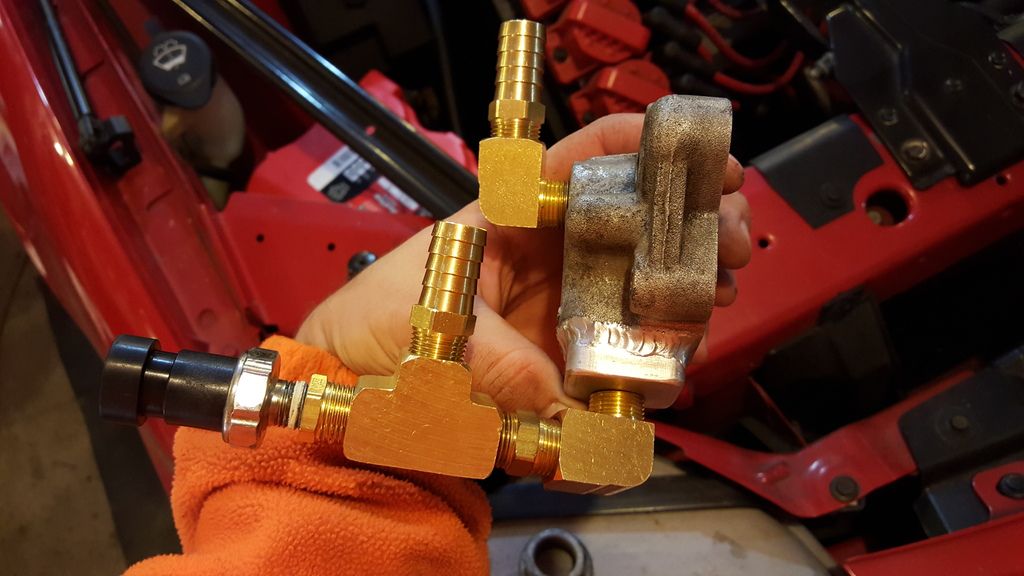

My puzzle pieces laid out

Basically, 1 and 2 are the pivot point for the pedal, and 3 bolts to the existing brake pedal bolt. It also is held by a bolt between 3 and 2 into the box.

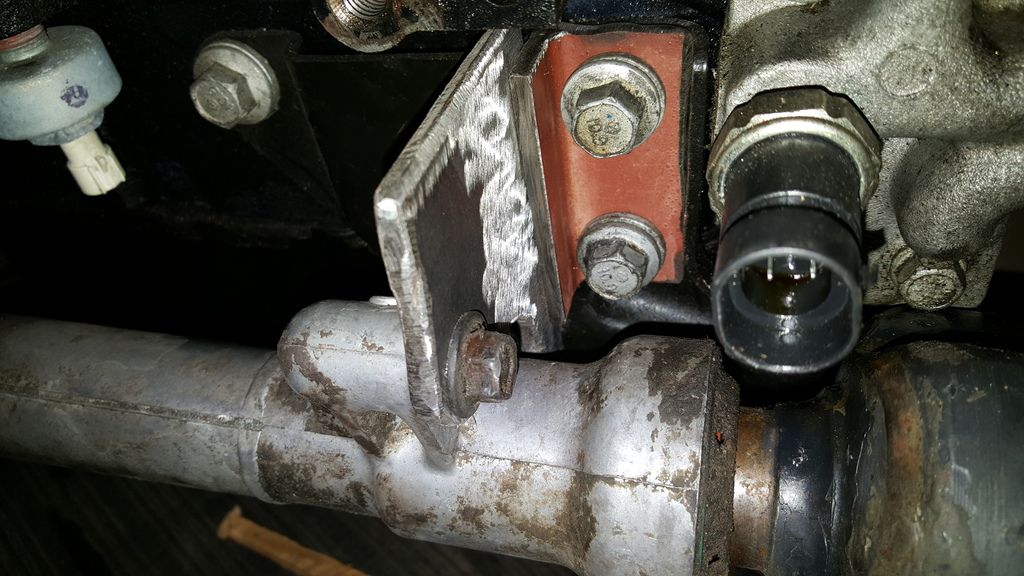

Another pic of it

Also, before that i cut the existing 98 brake pedal down

So, then there were 3

I used the brake light switch from the 89 as my cruise control disable, i will post better pics of it at some point, this is primitive compared to what i have now. Does work tho.

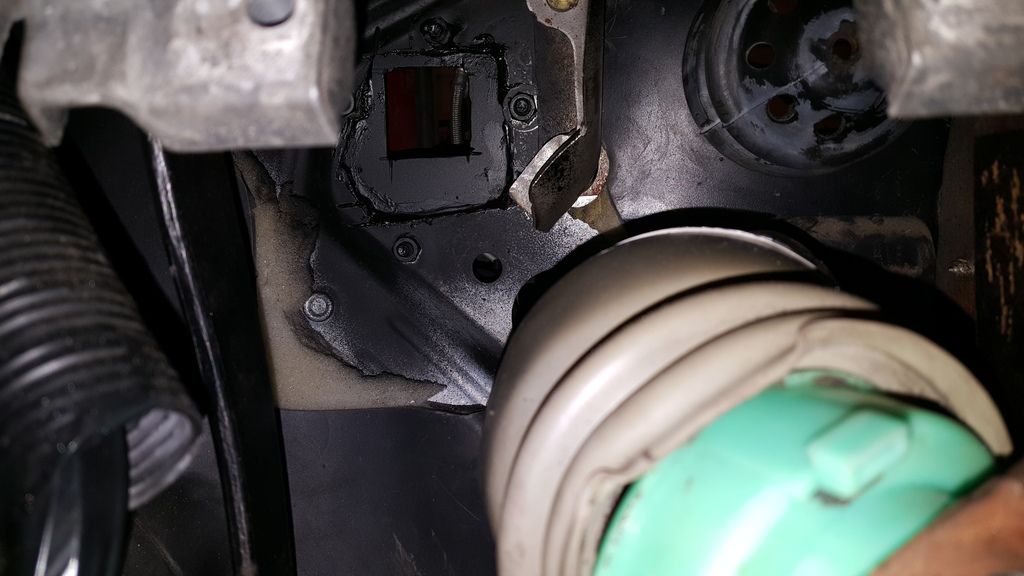

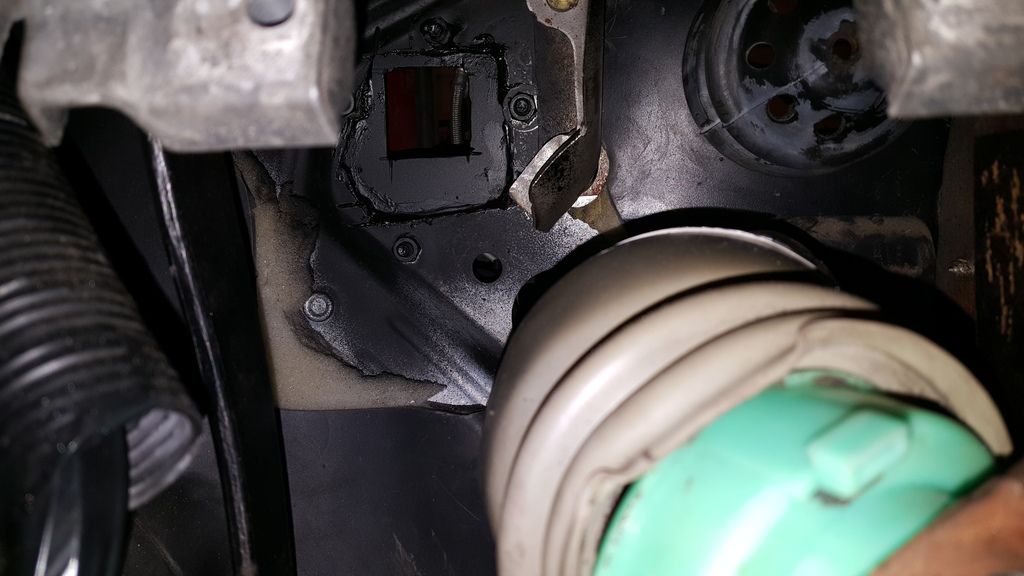

Next order of business was the clutch master cylinder firewall placement. Now, there is a hole under that piece of cardboard were the factory loom goes, there also happens to be a hole beneath that. The hole under the factory placement is unused and with a little adjustment will fit the factory loom.

Before

This is looking at it from in the car, i cut the area out that the cardboard was covering, and bolted my plate that i cut from my cardboard template. I already have the square for mounting the clutch mastercylinder cut in that plate. I then bolted it to the car, seam sealed it, then primed and painted it.

How it looks from the outside.

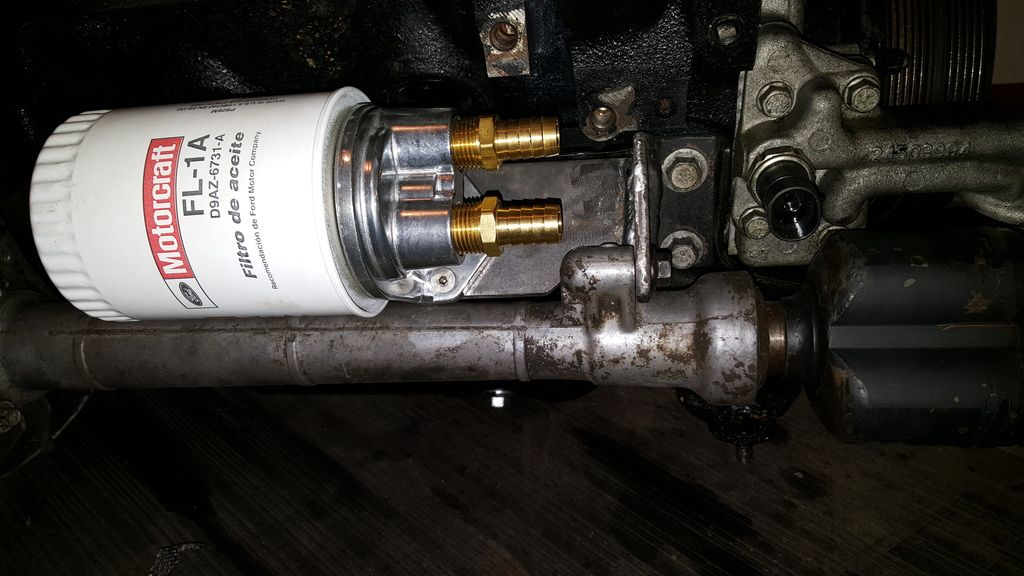

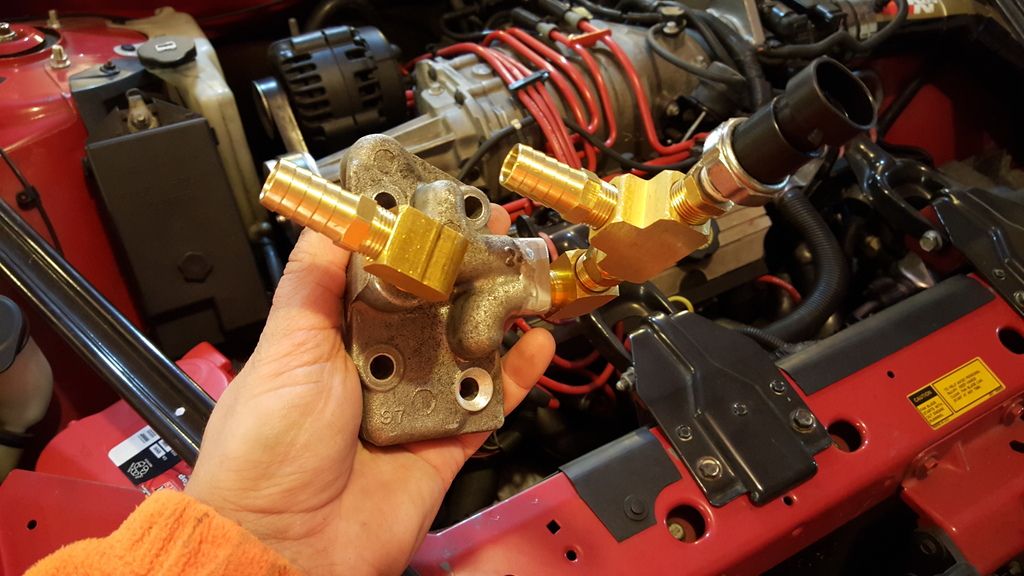

When you do these swaps ( 282 or 284) the clutch mastercylinder rod wont be long enough. So i welded an old brake booster rod on to it to get my length and angle right.

This swap is with the weaker little sister of the 284, the 282, found in fieros, cavaliers, sunfires, older grand prixs, low torque stuff like that. I may be wrong here, but i believe the rated torque on the 282 is right at 200 ftlbs MAX. So heres my thought process. I wanted to go manual with my GTP, not because of any issues with my auto tranny, i just decided it would make it a more enjoyable experience to drive. I knew that i did not want the headache of A: Finding a unicorn 284 in good condition, and B: not being able to ever rebuild it or get any parts. Also, damn that clutch cost alot for the 284!:th_thumb-down: Now, my mods are in my signature for my GTP, i knew going into this that the chances of nuking this thing the first pull were really good. Im not breaking the sound barrier performance wise, but i knew with a cam and 3.4 gen v the odds were against the 282. This thread will be continuously updated as to issues and mileage of the swap, to kinda see if this is a viable swap for people that have lower power builds. As i type this 9/14/17, i have 12400 miles on the build, roughly 500 of those are easy miles for clutch break in, the rest are not easy. So far this swap has done great, no issues, super fun, and is taking my beatings. This wont be a super detailed thread yet, but i will edit and add too it.

As a note before all the pics, If you ever plan to go turbo of do a max effort blower build, this is not the tranny for you, dont even bother.

So, this is the donor car. Shes an 89 grand prix coupe, rode hard, put away wet.

And heres the recipient of the swap, my 98 GTP.

See ya later you boring bastard

The teardown starts

4 speeds taking a vacation untill it goes in my 2000

The dirty 282 temporarily mated to my motor ( my gf photobombed my pic with her upper intake she just painted for her turbo 90 foxbody)

So after getting the motor out, i started on the interior, which is the hardest part of the swap.

Then the dash comes out

Just so we can get to the pedal box

89 pedal box on the left, 98 on the right. And no, the 89 box will not just bolt in, wish it would.

Now for me, adding the clutch pedal to the 98 pedal box was the hardest part of the swap, I just used the measurements off the old box , and started copying that with a piece of angle. Its crude, but i dont fabricate often. lol

Here is the general idea, just making the pivot point with the angle. It gets a little prettier as it progresses, but not much.

My puzzle pieces laid out

Basically, 1 and 2 are the pivot point for the pedal, and 3 bolts to the existing brake pedal bolt. It also is held by a bolt between 3 and 2 into the box.

Another pic of it

Also, before that i cut the existing 98 brake pedal down

So, then there were 3

I used the brake light switch from the 89 as my cruise control disable, i will post better pics of it at some point, this is primitive compared to what i have now. Does work tho.

Next order of business was the clutch master cylinder firewall placement. Now, there is a hole under that piece of cardboard were the factory loom goes, there also happens to be a hole beneath that. The hole under the factory placement is unused and with a little adjustment will fit the factory loom.

Before

This is looking at it from in the car, i cut the area out that the cardboard was covering, and bolted my plate that i cut from my cardboard template. I already have the square for mounting the clutch mastercylinder cut in that plate. I then bolted it to the car, seam sealed it, then primed and painted it.

How it looks from the outside.

When you do these swaps ( 282 or 284) the clutch mastercylinder rod wont be long enough. So i welded an old brake booster rod on to it to get my length and angle right.

Last edited: