USonuMabeaCh

New member

So i have the core and bolts from SSEILMNOP, the zzp heat exchanger, pump and mounting brack for the pump, and pigtail for the pump for the I/C. SSEI's thread seems to suggest 5/8ths heater hose AND adapting fittings, and also seems at parts not 100% up to date (even if it's updated later in the thread, it's so long it's ridiculous), but I see on WBS that they sell 3/4" hose, and ZZP doesnt state exactly what hoses and clamps and fittings are in their kit.

1.) I know that grey RTV for replacing the gaskets is what goes with SSEI's i/c, so I'll be buying that, how many tubes should I need, just 1?

2.) How much of what size heater hose should I get? If i dont have to put fittings that go from 5/8" to 3/4" by just using 3/4" hose, I'd rather do that, unless there's some problem with that that I'm unaware of?

3.) How many hose clamps? 4? more? I know this kind of depends on #2.

4.) fittings?

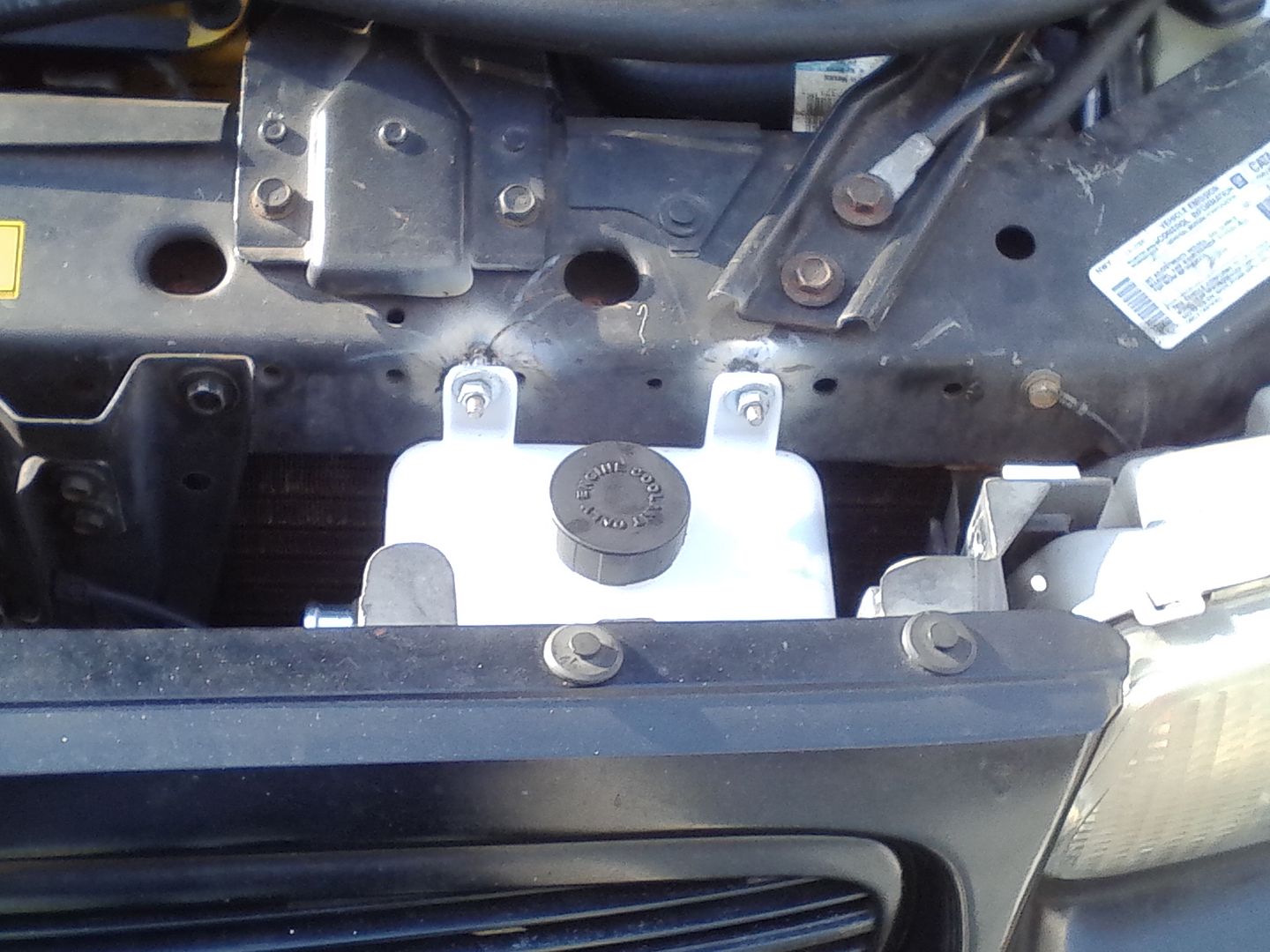

5.) What if anything will I need to mount the h/e?

1.) I know that grey RTV for replacing the gaskets is what goes with SSEI's i/c, so I'll be buying that, how many tubes should I need, just 1?

2.) How much of what size heater hose should I get? If i dont have to put fittings that go from 5/8" to 3/4" by just using 3/4" hose, I'd rather do that, unless there's some problem with that that I'm unaware of?

3.) How many hose clamps? 4? more? I know this kind of depends on #2.

4.) fittings?

5.) What if anything will I need to mount the h/e?