IndeedSS

SS-DD Level Member

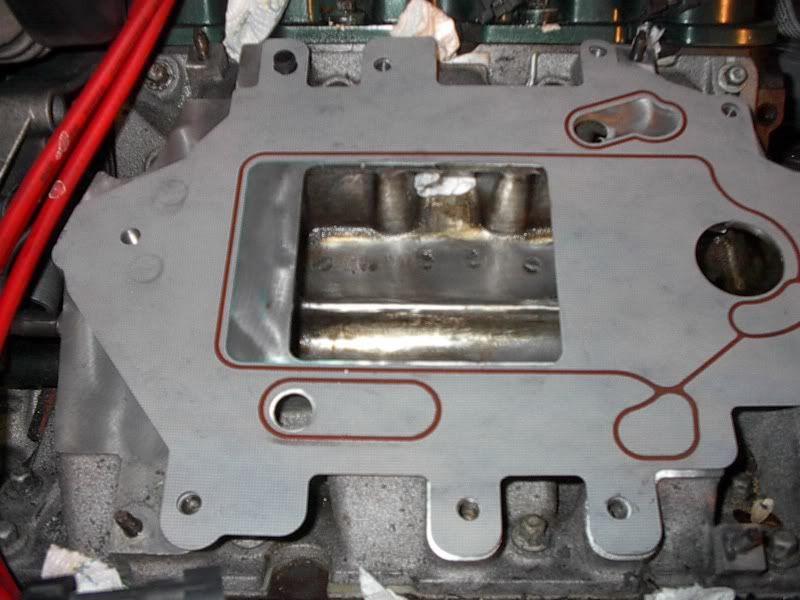

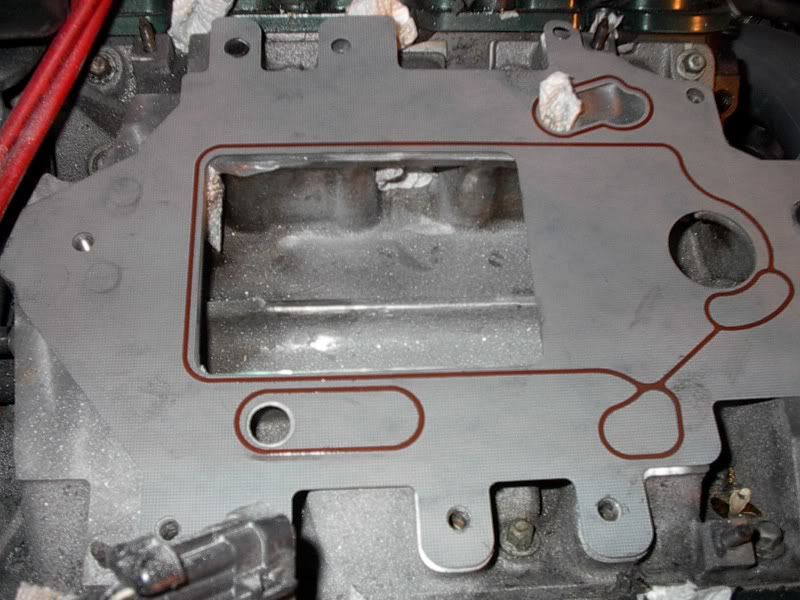

I looked at a gen 5 gasket laying on top of a garlock trimmed for an IC install. Wht I don't get, and something Dave (Trannyman) mentioned, is how much farther forward the gen 5 outlet is compared to a gen 3. When installing a Gen 5 gasket on a gen 3 IC install, what do you do about the large area where there is no gasket material? I'm sure it will seal, but it can't be good to allow pressure to continually blow through the gap where there is no gasket.