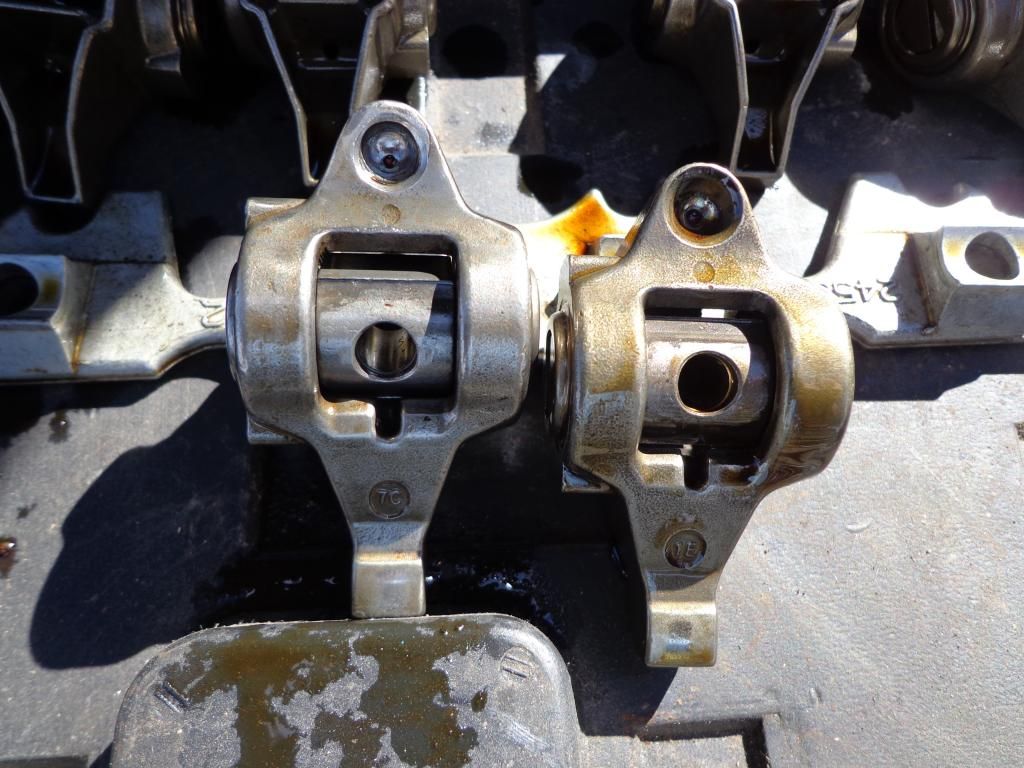

I've heard that a set of the 1.9 rockers zzp sells are the stock rockers and seat altered. I'm a cnc machinist by trade and was trying to specifically figure out how to do this myself. The only thing that makes sense to me at this point in time would be milling. 030" off the seat. I've asked many people close to me what they thought and no one really can say how it would work. I read on a post somewhere that they weld on them and then machine them back to their conformity with an extra .030 on them, but I find that hard to believe. It was just a random person that suggested this. Does anyone know for real?