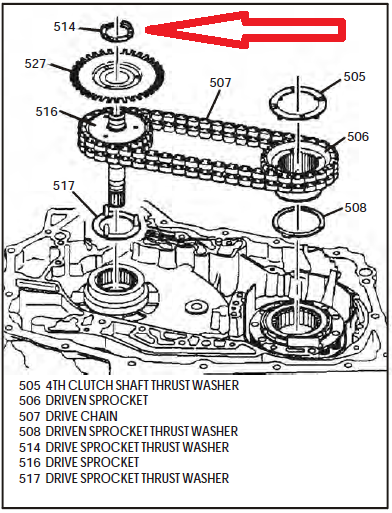

well, that thrust washer had three nipples that protruded from it and would engage into the holes in the gear that keep it in place. those were perfectly engaged all along. However, not knowing for sure what was behind there, i took the drive gear off to inspect as recommended. Today when i bought the new outter thrust washer, I could not just buy that one, i had to buy a kit that contained several. In my kit, there was also a brand new thrust washer for behind the gear. so, since i had it off, i replaced it as well, why not?.

while it was off, i was able to confirm there was nothing wrong back there. At least now i know for certain. I put the new thrust washers on, goo'd in place, and puts the gears back on. I tried to install the channel plate and again, the thing would tedder todder and not sit down correctly.

Since i know for certain the thrust washers are where they are supposed to be, and i measured the channel plate and transmission surfaces for flatness, i dont know what the heck is going on. the only thing i can speculate is the last teflon seal ring on the shaft. Maybe when i put the channel plate up there, that one seal does not drop in easy as the first one. I know i have looked at this every which way, its time to take action. I assembled it how it is. I might pay the price for it, but i dont see anything that is responcible for the tedder todder, i dont see where this has become an issue for anyone else, and i got all new parts in there, so im just gonna go for it.

I put the channel plate on for good and torqued down all the bolts per the manual. I did not hear any cracking or popping. If i had never felt that rocking, i would not have noticed it now for sure. it went flawlessly. After all the bolts were in and torqued, i checked all the way around the channel plate and did not see any gaps. I feel it is seated down properly now.

I'd say out of all the work i did on this transmission, this is the one thing i feel unsure about. Oh well, I am down to installing the wire harness and solinoids, then put the cover back on and subframe, etc. I think i can test drive it tonight for sure. Then I'll know.