glendayle

New member

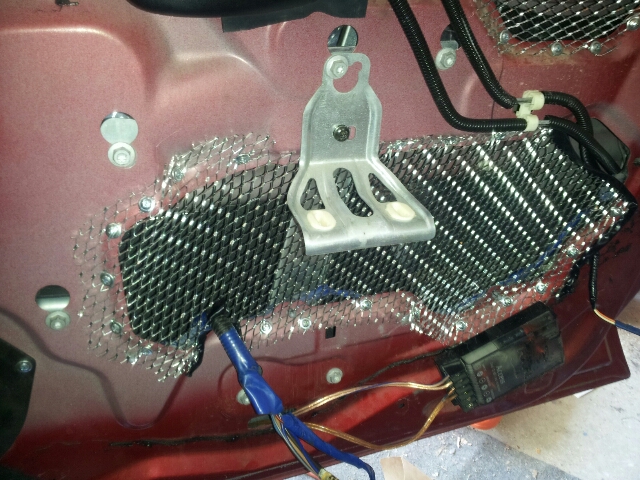

Picked up some of my parts for install of fuel lines. I only need to order a universal filter as I forgot to get one with my last order. Those Swagelok fittings weren't cheap.

Also, Bill, if you read this, I may still need help on which wire is the correct wire to tap for the mirror turn signal lights. I couldn't figure it out, so I just ran the wires all the way to the taillights. I just need to figure out which one controls the blinker and then I can tap that and ground the return.

Also, Bill, if you read this, I may still need help on which wire is the correct wire to tap for the mirror turn signal lights. I couldn't figure it out, so I just ran the wires all the way to the taillights. I just need to figure out which one controls the blinker and then I can tap that and ground the return.