TurboKent

New member

Trannyman started a thread about devistated transmissions so i thought i would do the same for any engine. Post'em up!

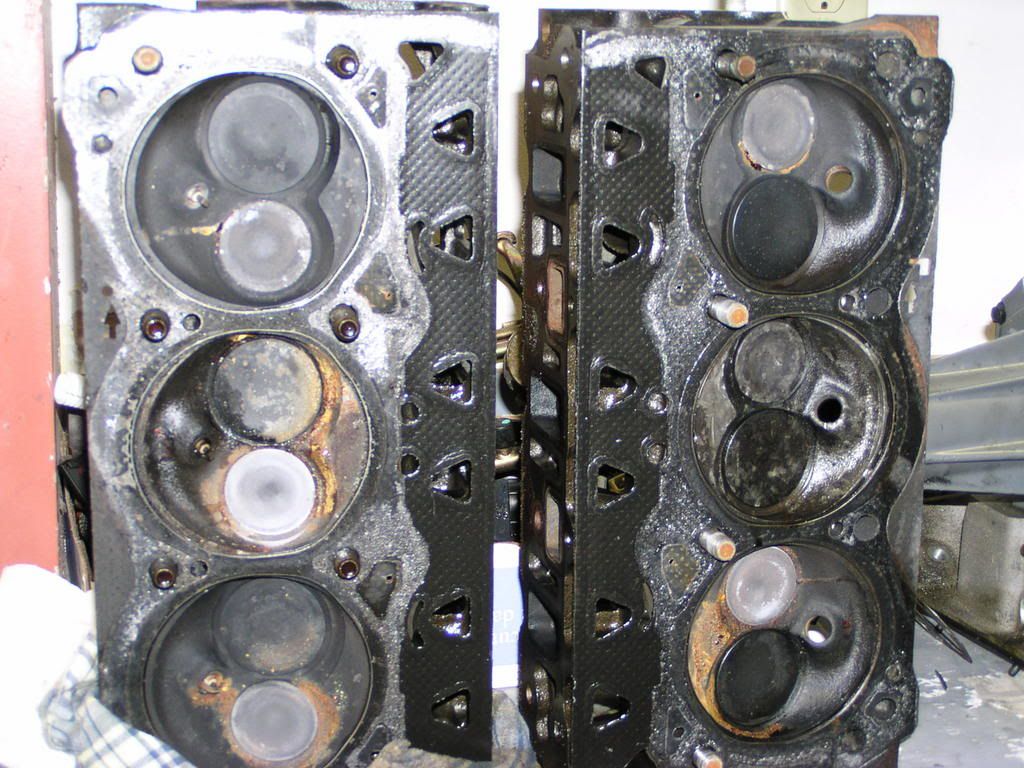

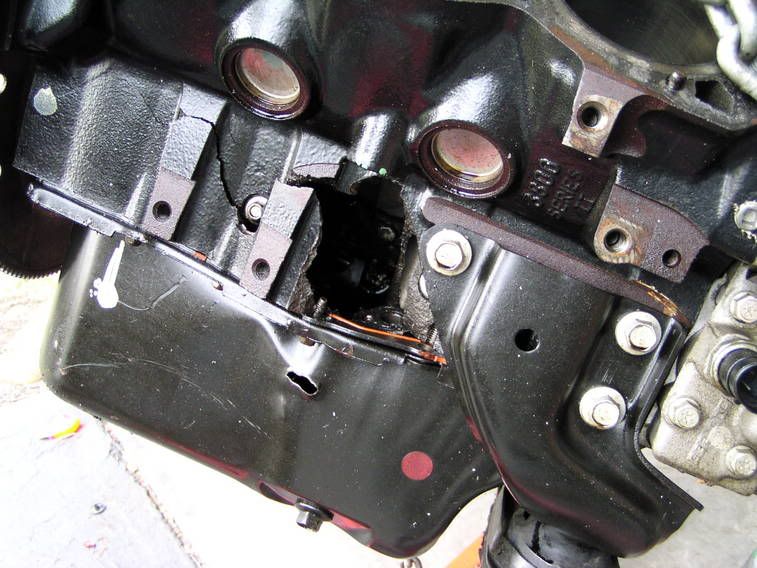

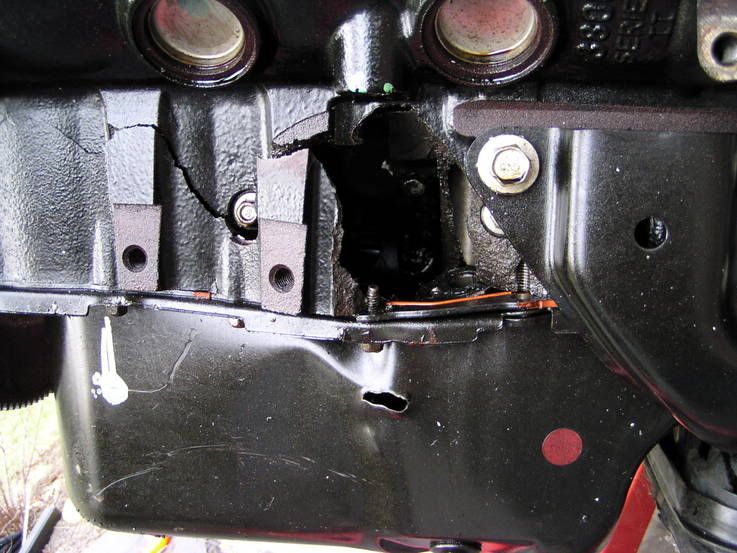

Sad thing is that was just the first engine. I have yet to open up the other one to see what when on there. All of this due to a small vacuum line not connected correctly. Oops.

Sad thing is that was just the first engine. I have yet to open up the other one to see what when on there. All of this due to a small vacuum line not connected correctly. Oops.