minichopper6hp

Banned - Busted For Scamming

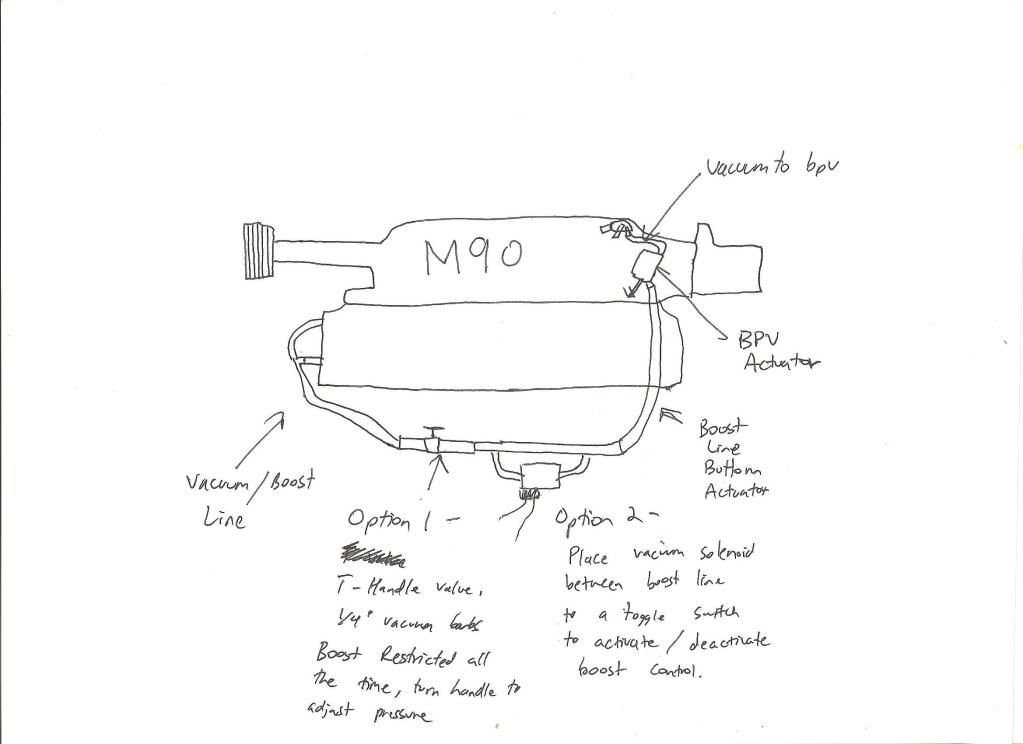

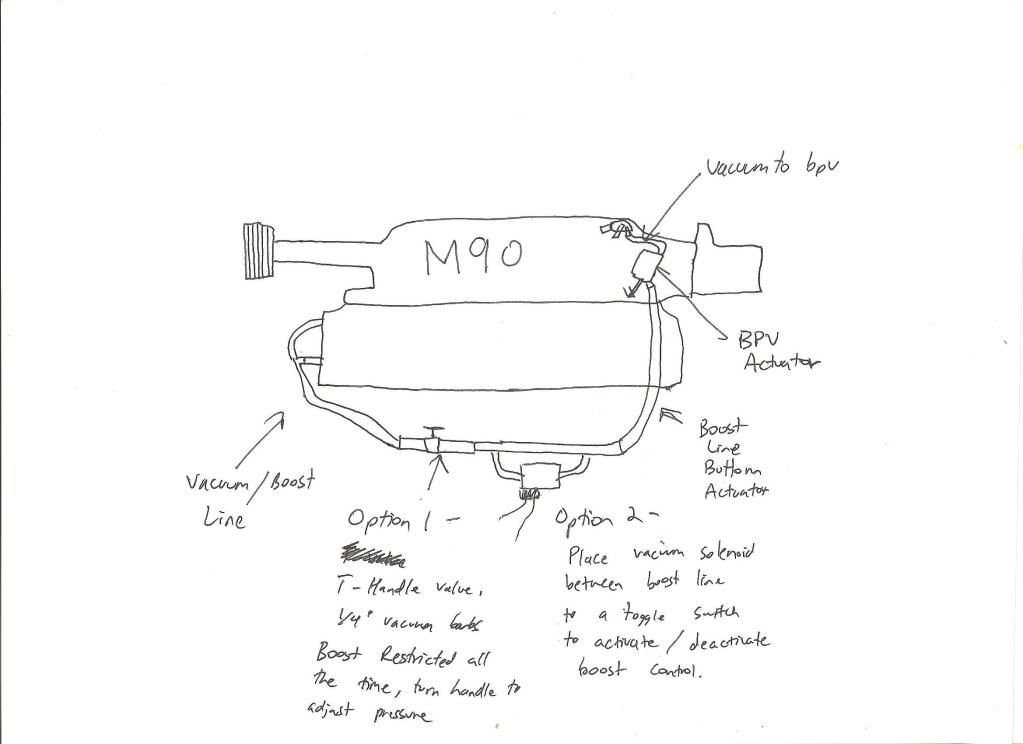

Would there be an effective way to make a boost controller using the bbv to limit the boost of the supercharger? I would like to put on my 3.0 pulley and retain the current 10 psi. Reason is that i dont want to have to keep swapping pulleys everytime i want to change boost level. Also would be good b/c im going to have my intercooler on a switch, with a switch that i could up the boost when the ic is running only. Today i put a restrictor inline with a hose going from the lim to the bottom of the bbv where the factory solenoid was. I originally was running 10 psi, and now am running 4 psi as an experiment. I think that we could adapt the adjustable boost controller like they use on the turbo wastegate. Any ideas?

Logan

Logan

Last edited: