PWNED

New member

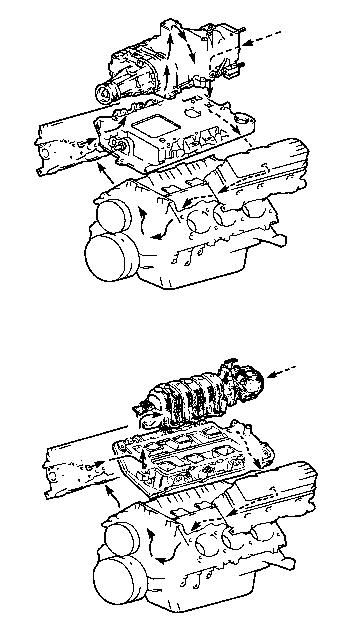

The first install I did not rtv enough to the coolant elbow side creating a vacuum leak.

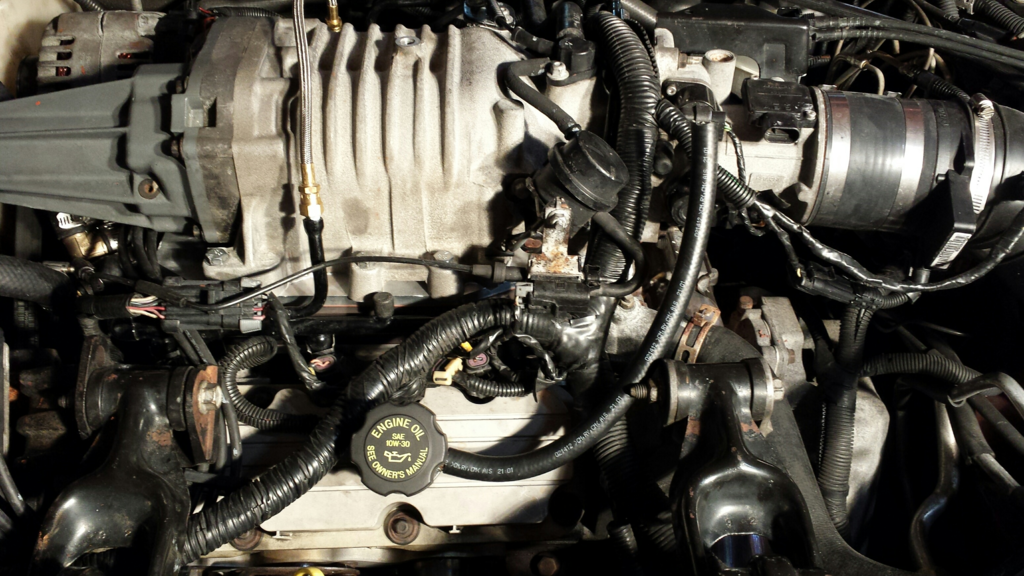

Second I rtved too much as the top half split and stuck to the SC. So the rtv blocked the front and rear pcv passages. Thus I got the worse whistle EVER.

Third....

I just cleared out every hole and re rtved. No crazily. Started it up and it is still trying to suck in the oil cap.......WTF could be wrong here!?

Second I rtved too much as the top half split and stuck to the SC. So the rtv blocked the front and rear pcv passages. Thus I got the worse whistle EVER.

Third....

I just cleared out every hole and re rtved. No crazily. Started it up and it is still trying to suck in the oil cap.......WTF could be wrong here!?