TwinV6GTP

New member

We are doing a budget turbo build for my own fun here at the shop. The idea is to spend as little as possible and have some fun at the same time.

This exercise is basically to find a way to make decent power with using the least amount of aftermarket parts as possible.

So for this project, we took mainly parts that were laying around the shop. The priciest item in the build is the GTX3076 turbocharger good for 600HP on a 4 cylinder engine.

It is not the ideal turbo however it will probably be good for my 100% stock 3.8 with stock stall converter. it will make it easy to spool up.

I'm using stock fuel injectors with higher fuel pressure and high pressure fuel pump and a small fuel cell. Of course higher pressure comes with an adjustable regulator.

Methanol injection at 70% meth to 30% water will help add more fuel to the mix to make 500HP+

Yes injector duty will be very high.

We have the full 3" exhaust I had made for my 12 sec street tire grand prix. With the V-band I will be able to switch to a small straight pipe out of the hood if I decide to ditch the street sound for a few extra tenths !

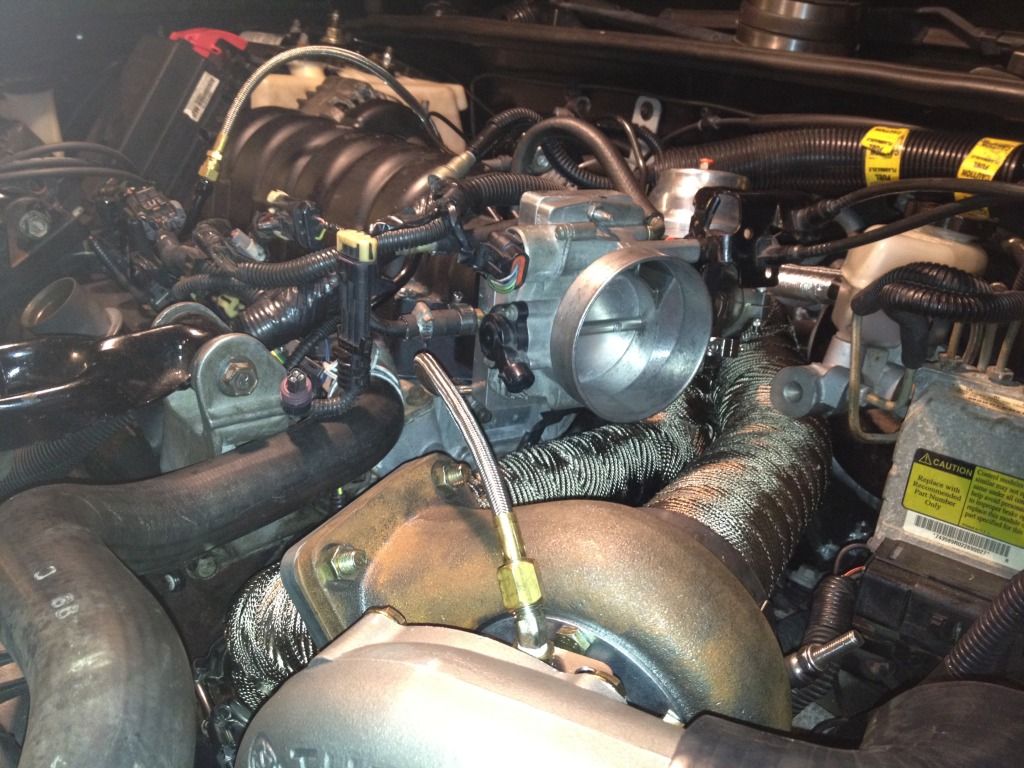

I used a 2005 Grand Prix intake manifold for this build to improve distribution in the cylinders. I didn't like the opening on the supercharger intake, it favors the middle cylinders.

I will tell you that I will be going with the simple block off plate next time or build a new top manifold from scratch. It was not worth the hassle...

We had to make a TB adapter plate from scratch

Took a lot of weight out of the car. used my new mechanic for this job. I can't believe how much we took out. We weighed everything, although we didn't put it on paper, it has to be at least 500lbs.

using a momo seat as well.

It will be first tuned on the street and then mainly used at the drag stip. But I will try to keep a "street" aspect to it. I don't want it looking like a Pro car because it isn't. No where near the budget.

The total cost of the build so far without the labor counted (lots of hours) is around 4000$ including the car. Most of which can be transferred to the real race car (twin engine) once we are done.

Noticed the welded up injector ports in the 05 N/A intake. Lots of mods in that intake. added bungs with fittings for vacuum and boost lines.

Improved PCV function as well.

This exercise is basically to find a way to make decent power with using the least amount of aftermarket parts as possible.

So for this project, we took mainly parts that were laying around the shop. The priciest item in the build is the GTX3076 turbocharger good for 600HP on a 4 cylinder engine.

It is not the ideal turbo however it will probably be good for my 100% stock 3.8 with stock stall converter. it will make it easy to spool up.

I'm using stock fuel injectors with higher fuel pressure and high pressure fuel pump and a small fuel cell. Of course higher pressure comes with an adjustable regulator.

Methanol injection at 70% meth to 30% water will help add more fuel to the mix to make 500HP+

Yes injector duty will be very high.

We have the full 3" exhaust I had made for my 12 sec street tire grand prix. With the V-band I will be able to switch to a small straight pipe out of the hood if I decide to ditch the street sound for a few extra tenths !

I used a 2005 Grand Prix intake manifold for this build to improve distribution in the cylinders. I didn't like the opening on the supercharger intake, it favors the middle cylinders.

I will tell you that I will be going with the simple block off plate next time or build a new top manifold from scratch. It was not worth the hassle...

We had to make a TB adapter plate from scratch

Took a lot of weight out of the car. used my new mechanic for this job. I can't believe how much we took out. We weighed everything, although we didn't put it on paper, it has to be at least 500lbs.

using a momo seat as well.

It will be first tuned on the street and then mainly used at the drag stip. But I will try to keep a "street" aspect to it. I don't want it looking like a Pro car because it isn't. No where near the budget.

The total cost of the build so far without the labor counted (lots of hours) is around 4000$ including the car. Most of which can be transferred to the real race car (twin engine) once we are done.

Noticed the welded up injector ports in the 05 N/A intake. Lots of mods in that intake. added bungs with fittings for vacuum and boost lines.

Improved PCV function as well.