Below Average Joe

New member

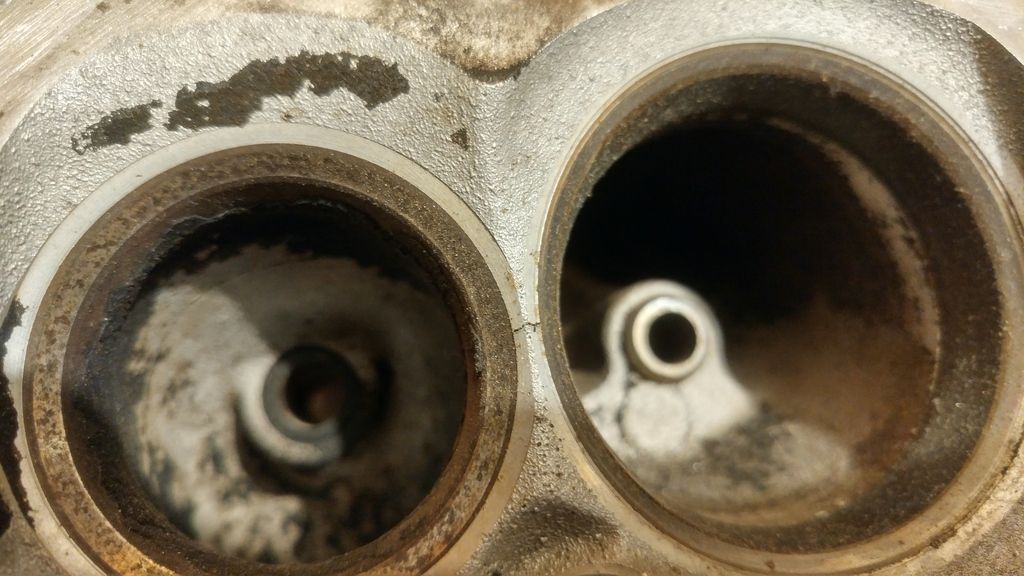

So Sunday I picked up an LQ4 for really cheap knowing that there was an issue. Upon getting it to my house and in the garage, I pulled off the heads to see what I will be working with. This will be a father and son project, so it will get worked on when we have time. I will update when more progress happens. I'll let the pictures do the talking.

Also got this little guide. Looks like I will be reading up before we go any further.

Also got this little guide. Looks like I will be reading up before we go any further.