Pure2sin

New member

After cutting my own gaskets out of a material PRJ suggested, I still had leaks. I then spread RTV all over the gaskets on both sides and installed them. This made for a tight seal but was way too hard to take off and broke my core upon removal.

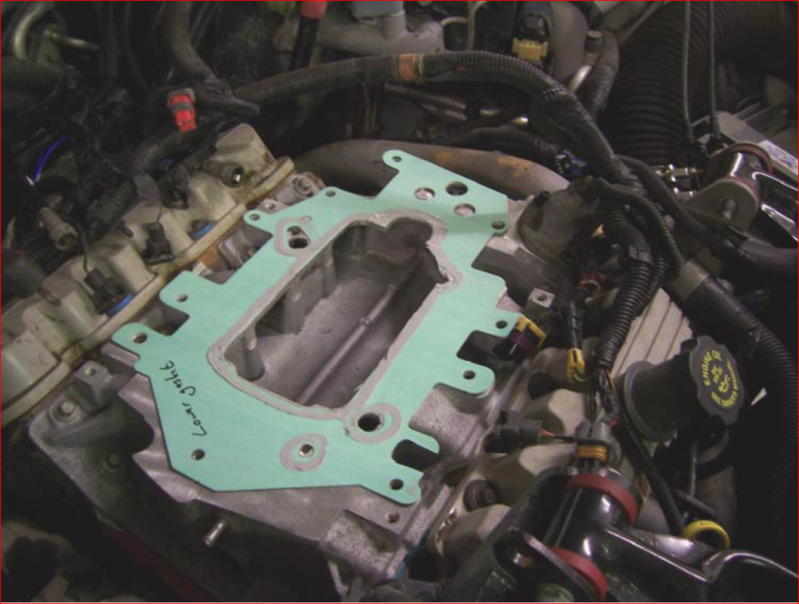

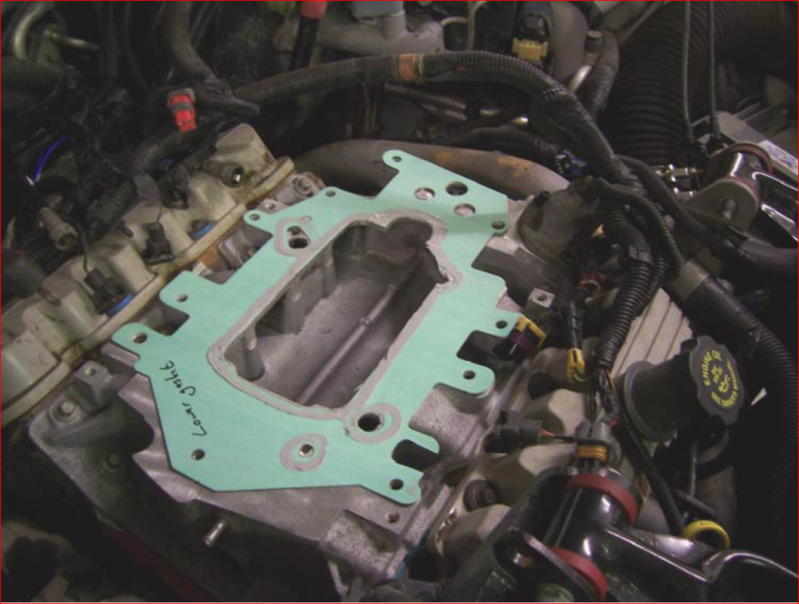

Instead of buying some more of the expensive material again I went to O'Reillys and bought some material I found there for $5 a roll. I then cut some gaskets out of that:

It's 1/16 of a inch and made of rubber and fiber (Fel-Pro #3157). It should work out well for this application and it way more flexible and should seal better than Garlock gaskets.

The question I have now is not to use RTV or not, but how much to use?

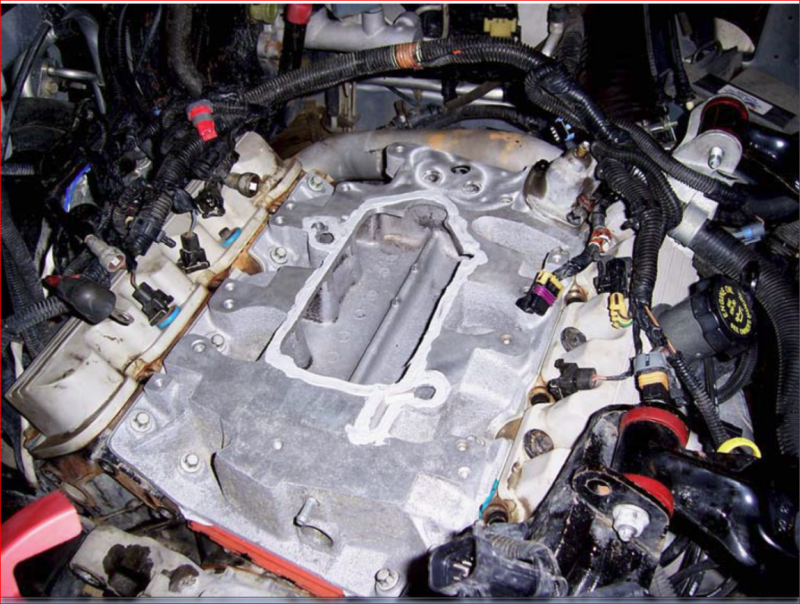

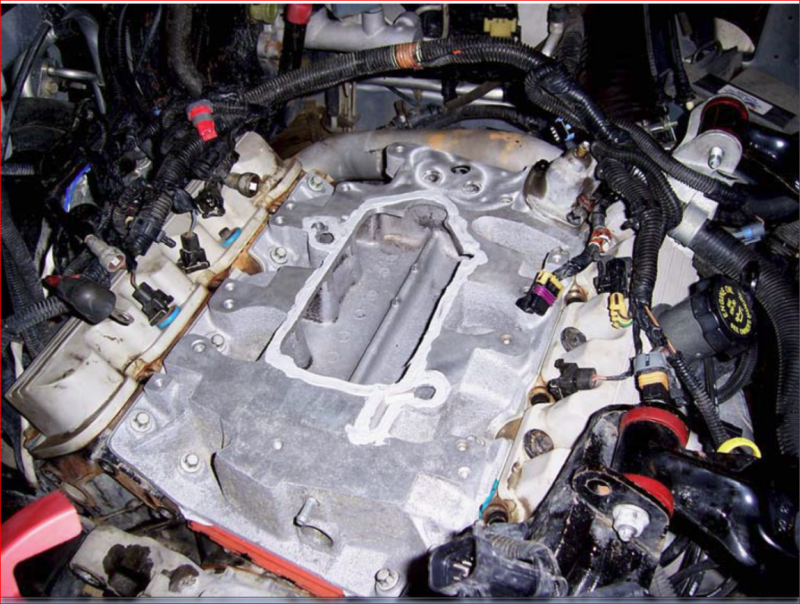

I found these pictures on what ZZP says for the install of their cores with Garlocks. I am wondering if anyone has put the RTV on like this with success.

Instead of buying some more of the expensive material again I went to O'Reillys and bought some material I found there for $5 a roll. I then cut some gaskets out of that:

It's 1/16 of a inch and made of rubber and fiber (Fel-Pro #3157). It should work out well for this application and it way more flexible and should seal better than Garlock gaskets.

The question I have now is not to use RTV or not, but how much to use?

I found these pictures on what ZZP says for the install of their cores with Garlocks. I am wondering if anyone has put the RTV on like this with success.