Iron Indian

New member

Hey Guys,

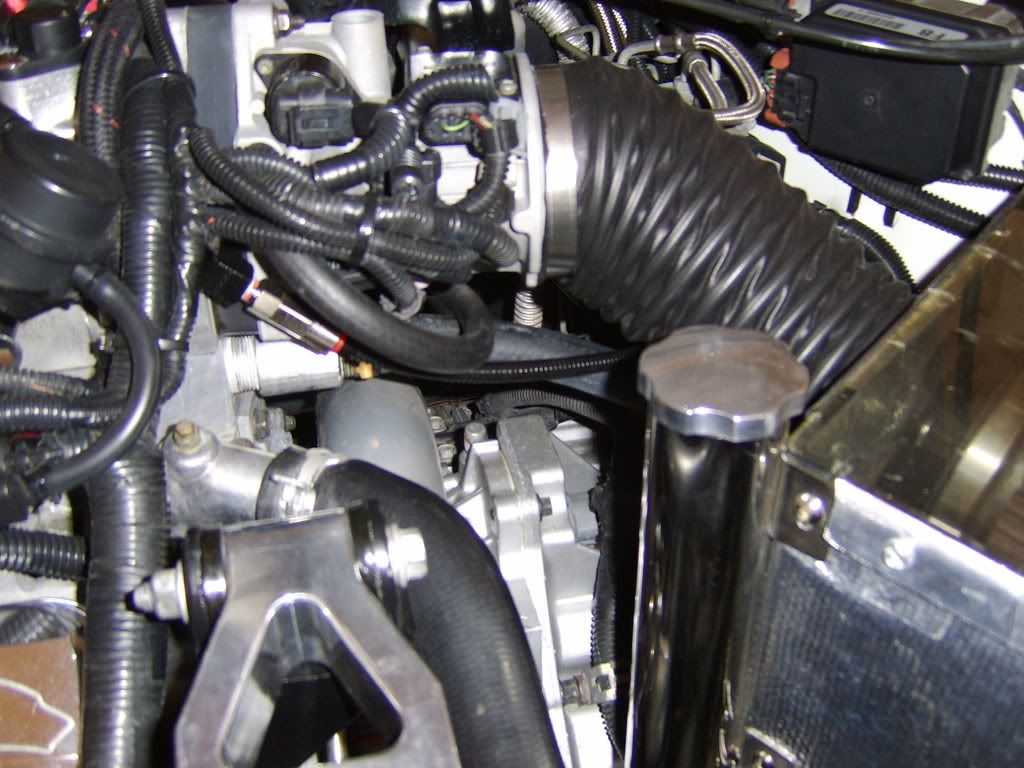

I haven't been on much lately, been working mostly 16 hour days which leaves me pretty much worn out. I had a little bit of time on Saturday and Sunday to get my Devilsown Stage 2 Progressive 3800 Alky Kit installed on my 1999 GTP. Here are my pics...

Bumper removed ready to get started...

Theres my washer tank, time for some modifications...

Nice flat indention, perfect for a fitting...

Scoring a mark/bit guide...

Drilling the hole...

Flushing out the shavings with distilled water...

Tapping threads into the tank using an 1/8"-27 NPT tap...

I haven't been on much lately, been working mostly 16 hour days which leaves me pretty much worn out. I had a little bit of time on Saturday and Sunday to get my Devilsown Stage 2 Progressive 3800 Alky Kit installed on my 1999 GTP. Here are my pics...

Bumper removed ready to get started...

Theres my washer tank, time for some modifications...

Nice flat indention, perfect for a fitting...

Scoring a mark/bit guide...

Drilling the hole...

Flushing out the shavings with distilled water...

Tapping threads into the tank using an 1/8"-27 NPT tap...

Last edited by a moderator: