Turbocharged400sbc

New member

my issue is with a divided T4 with a giant AR on a small displacement v6 with a rotating assembly thats better for making power down low/mid range rpm.

i have a feeling your leaving a ton of under the curve performance off your car.

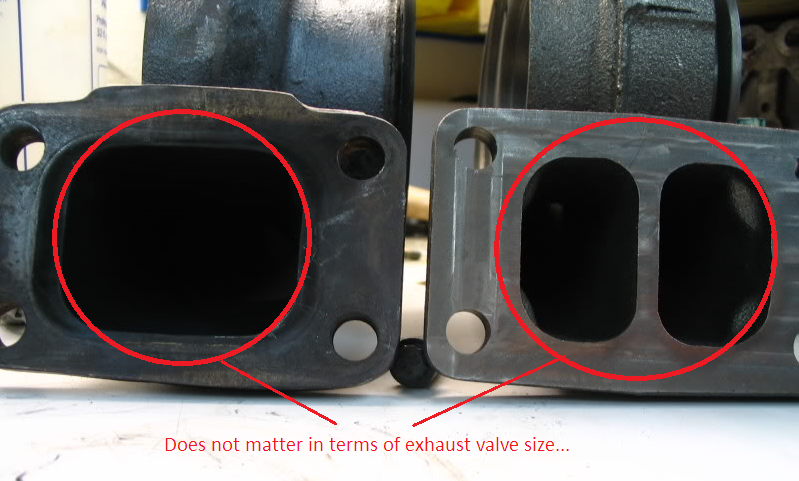

i doubt its a divided T3, which at least the area of the one port is just a hair bigger cross sectional area as one exhaust port.

a divided T4 has each port a good bit bigger than each of our intake ports. no mater what you do with the piping that increase in cross sectional area is creating a pressure drop as it enters the turbine scroll. sorta not what the pulse tuning is about, kinda hard to keep that pressure wave energy moving when the area of the pipe increases as much as it does

and since pulse tuning is to help at low/mid range Rpm's by spooling the turbo....youd probably make way more power at the bottom half of your curve if you kept the exhaust gas velocity up.

ive seen guys get around large AR turbines by running the pipes through the flange and leaving them long enough that they form to the inside of the turbine scroll artificially reducing the AR and keeping the pipe volume/wave speed constant.

im just saying that we were lighting off the turbo before 2700 rpm, and made of 400ftlbs of tq at 3k rpm with 500 ftlbs by 3750, 575 by the time we got to 5k. HP got to 608 by 5400rpm at a lean fall off due to fuel pressure dropping. we did that at 18psi and our compressor is good to 26.

primary's are 1.625 od and secondary's are 2"

im really just saying youd do more for your lower rpm performance if you at least swapped out the turbine housing for a .68 AR and kept your current piping.

if that is a divided T4 with that big of an AR id figure on you moving the bottom end of the Tq curve another 1,000rpm closer to idle and not change your current power peak even though the tq curve would be higher nearly the whole way down.

that or youd get a bump using a more powerfull squirt using one of the sound performance/others scroll closing plate (really only for open collector merges)

meh i like discussions. i spent alot of time talking to turbo buick guys doing the math for our stuff.

its a great motor but when they shortened the deck height and made it a much higher rod/stroke angularity....they sorta killed the top end

i have a feeling your leaving a ton of under the curve performance off your car.

i doubt its a divided T3, which at least the area of the one port is just a hair bigger cross sectional area as one exhaust port.

a divided T4 has each port a good bit bigger than each of our intake ports. no mater what you do with the piping that increase in cross sectional area is creating a pressure drop as it enters the turbine scroll. sorta not what the pulse tuning is about, kinda hard to keep that pressure wave energy moving when the area of the pipe increases as much as it does

and since pulse tuning is to help at low/mid range Rpm's by spooling the turbo....youd probably make way more power at the bottom half of your curve if you kept the exhaust gas velocity up.

ive seen guys get around large AR turbines by running the pipes through the flange and leaving them long enough that they form to the inside of the turbine scroll artificially reducing the AR and keeping the pipe volume/wave speed constant.

im just saying that we were lighting off the turbo before 2700 rpm, and made of 400ftlbs of tq at 3k rpm with 500 ftlbs by 3750, 575 by the time we got to 5k. HP got to 608 by 5400rpm at a lean fall off due to fuel pressure dropping. we did that at 18psi and our compressor is good to 26.

primary's are 1.625 od and secondary's are 2"

im really just saying youd do more for your lower rpm performance if you at least swapped out the turbine housing for a .68 AR and kept your current piping.

if that is a divided T4 with that big of an AR id figure on you moving the bottom end of the Tq curve another 1,000rpm closer to idle and not change your current power peak even though the tq curve would be higher nearly the whole way down.

that or youd get a bump using a more powerfull squirt using one of the sound performance/others scroll closing plate (really only for open collector merges)

meh i like discussions. i spent alot of time talking to turbo buick guys doing the math for our stuff.

its a great motor but when they shortened the deck height and made it a much higher rod/stroke angularity....they sorta killed the top end