David99GTP

New member

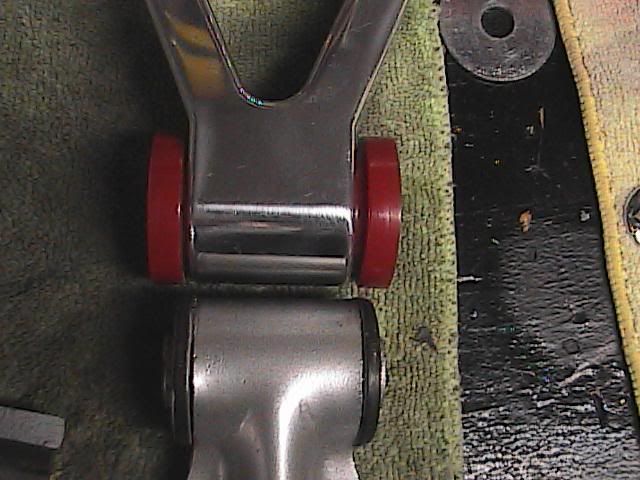

Well I bought my polished dog bones from 3800, and some red poly ounts from Intense. The new bushings are a bit wider then the stock and when I forced them into my right(drivers) side mount bracket.... SNAP. The bracket broke. :th_angry-censored::th_angry-tantrum:

The real crappy part is I just picked up the bracket from the chromer today. I am sooo POed right now I am seeing red. Anyone have any advice? Any experience with these poly bushings?

The real crappy part is I just picked up the bracket from the chromer today. I am sooo POed right now I am seeing red. Anyone have any advice? Any experience with these poly bushings?