|

|

I had to buy a couple odds and ends and it'll probably need tires soon, but I'm still pretty happy with it. I bought it just to get the truck to the exhaust shop, and the emissions testing station. Anything beyond that is just a bonus. Maybe once the truck is finished, I'll start looking for w-body's with trans problems to fix and flip. Also need to find a truck willing to give up it's motor for my '84 K10.

I guess if I break the S10 at the track, I'll be able to get it home too...

Yup! Just need to:

Wire the fans

finish the intake piping

Redrill the axles

assemble the rear

install the rear

plumb the brakes

get the driveshaft shortened, balanced and installed

get exhaust

get inspected

get registered

get insured

I'm sure there's something missing... But after all that, yes, BURNOUTS!

(Five minutes later)

Rotate tires, and more BURNOUTS!

(Five minutes after that)

Shopping for new/used tires

(Sometime after that)

More BURNOUTS!

See a pattern?

Still working on fan wiring. Managed to find just enough real estate on the firewall for the fan relay/fuse block. Not much room for anything else. Installing the HydoBoost should open things up a little.

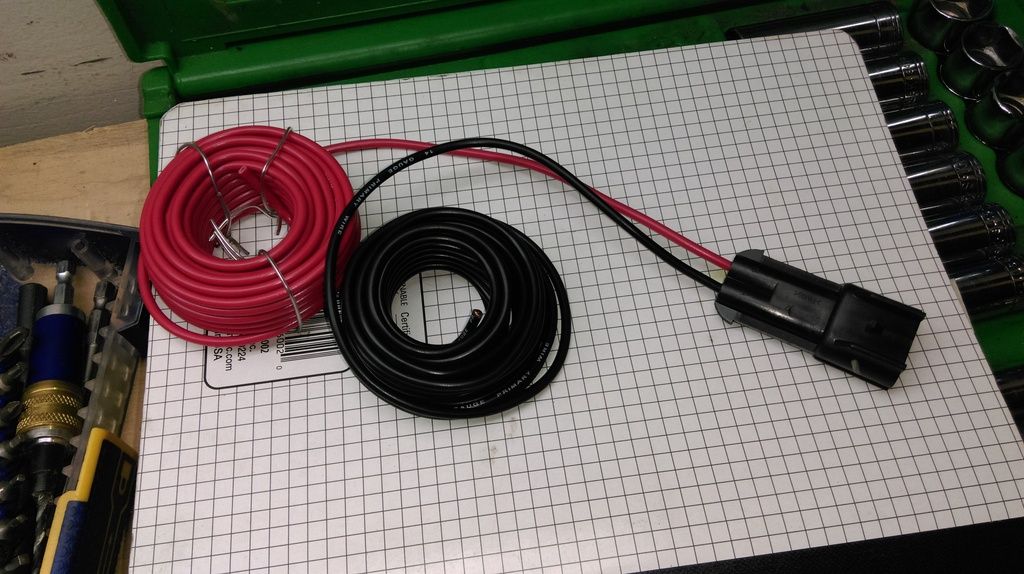

The fans came with the female connector end, so that was nice. Just need to add wire.

fans done yet?

Burnouts yet then?

I made a couple good oopsie smoke shows in the GTP today. Thought of you.

After you get done bouncing up and down in the seat laughing and clapping as you fog yourself... the excitement "wears thin" just like them treads!

Yeah, I'm sure it will get old eventually, but I've got a couple kids that will enjoy it long after I'm over it. Let's not forget the doughnut/drift factor either. There's more to burnouts that just leaving two straight lines. With the right amount of practice, I should be able to parallel park anywhere!

I cut out of work early yesterday to pick up my completed housing

Under $75 to chop the long tube down 2-7/8", fixture weld, and install a new pinion seal (that I provided). All work done by Tucson Differential. http://www.tucsondifferential.com/ We'll see how it all works out, but so far I'm pretty happy.

that might be one of the best 35 dollar weld ive ever seen lol

at any price thats one buttery looking weld.

Been a while sine I was on here.

Coming along nicely I see!

nice yoke. i like to dip toast in mine lol

^^^^ "The Surgeon General recommends against consuming raw or undercooked foods"...lol Me too, and the home fries.

You guys are dorks...

Fans function perfectly under PCM control. Check that off the list. Time to work on redrilling the axles.

I'll see what McMaster and MSC have to help me out.

Well, with all the things (I think) I need to redrill the axles on order, it's time to address the spring perch location and angle. Did a bunch of measuring. Here's what I came up with.

According to my angle finder, the truck frame is at 0°, or close enough to zero that I'm not going to factor it in. The 80e is 4° nose down. So if my thinking is correct, the perches on the 8.8 should be set 38-1/2" apart, and the pinion should be 4° nose up. This would make the trans output shaft and rear pinion parallel. Which, in the end is what really matters.

I put the 8.8 on a set of stands and leveled it out to the perches. It measures 10° nose up. Not that that matters. Just wanted a reference.

Couldn't take a picture of the output angle. My phone is my angle finder...

4º seems a little high but I've seen worse.

I'd honestly just shim the transmission mount with some washer to get closer to 1-2º down, then angle the rear diff at 0-1º up because the pinion will want to rise under heavy throttle with a good amount of power. In theory at normal cruise it shouldn't cause any vibrations being only 1-2º different between the two when bumming around.

You know... That's not a bad idea. I was really okay with 4°, but hearing you say that, I think I'll get under there tomorrow and see how much I can raise it without touching the tunnel. It would also help with my header/steering shaft clearance. I can only assume they (the motor/trans mount company) engineer it with that much angle to clear the tunnel, but I seem to remember there being ample room above the trans. We shall see.

Thanks for that input!

id wait till the rear is under the truck and on its own weight, then start to mess with the angle. never know until its on the floor.

you'll be doing a 4 link soon enough who we kidding lol

| « Previous Thread | Next Thread » |