Really? At 111k and well maintained? I see a ton of used ones, doesn't seem like something to fail often.

|

|

Really? At 111k and well maintained? I see a ton of used ones, doesn't seem like something to fail often.

I've saw them Broken before 100k.

just depends on driving style. If it gets WOT often then you should get one just in case. If you drive it like G'ma then your probably ok.

As far as I know it wasn't beaten on, and I only went wot after the fluid change and pretty rarely overall.

The previous owner had it 3 years and was driven by his daughter, going to and from college in northern Mi so I doubt there was any wot.

I'll just inspect it when I get in there. If it's worn it will get put on hold and I'll drive the "back-up car" until it comes in. Really the family's extra car.

It may be ok. But it'll be one of the rare ones if it is. Normally they strip the teeth off of one end. You'll have to pull it out of the convertor to check it.

Good luck with it man, hope everything goes smooth. Let us know if you run into any trouble.

I haven't seen as many pump shafts bas a Twizted, but it's fairly cheap while you are in there. The only soleniod I'd replace is the EPC. The rest don't typically fail, at least not enough to replace now. 4th shaft yes, channel plate gaskets yes.

And.. me personally.. I'd follow the how to I wrote on it. But that's me.

I've been looking at that post you wrote for a little while now(months really), anticipating doing this very thing. My torque converter locks very slowly while all other gears shift normally. Then when it gets to full operating temp after a half hour or so of driving, I can tell all gears slow a bit and the torque converter locks really slow. In the morning when it's cold it locks just fine, pretty quick. That's why I wanted to replace it. Or could it be caused by low trans pressure alone? I do know they go bad often by 200k, they have trouble unlocking on acceleration. I ususlly see the 4th gear hub go by 150k, although the van(Montana) at my work is at 197k all original with a working 4th. It has the tcc solenoid problem though. So you really think I should leave out the TCC solenoid too? As long as it has nothing to do with it locking slowly I could leave it out. If it is possible to cause it I'll replace it.

Last edited by 02NavyBlue; 09-13-2013 at 05:06 PM.

Parts have been ordered. I'm looking into getting those channel plate gaskets from TEP.

Edit: channel plate gaskets ordered for $23.55

Last edited by 02NavyBlue; 09-14-2013 at 10:24 PM.

Just found this: "Most solenoids can be removed by pulling the steel clip from the exposed valve body channel EXCEPT the one for the TCC/PWM solenoid, you must remove the oil pump first for that solenoid."

Well I'll just post the site, it's pretty in depth http://www.gmtruckhq.com/drivetrain/...rade-3517.html

The oil pump is about 10 bolts and no gasket. Leave the silver bolt in, it'll hold the cover on and you will be able to install/remove without extra work.

FYI hub shafts

See the silver screw?

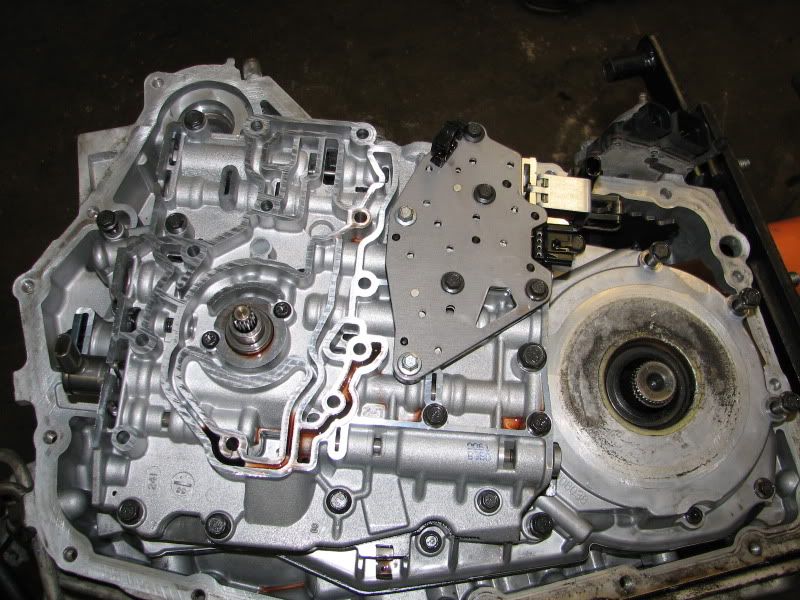

Here's pump off and looking right at the tcc soleniod and it's clip. You can probably sneak it out with the pump on, but it's easier out.

Thanks ^ I'll get some pick tools, I have none so far.

The job starts tomorrow around 4, and can carry on to Saturday if needed, the weather looks good. Wish me luck.

Good reference material:

Component Resistance

Component Pass Thru Pins Resistance at 20°C (68°F) Resistance at 88°C (190°F) Resistance to Ground (Case) 1-2 Shift Solenoid Valve A, E 19-24 Ω 24-31 Ω Greater than 250 K Ω 2-3 Shift Solenoid Valve B, E 19-24 Ω 24-31 Ω Greater than 250 K Ω Torque Converter Clutch Pulse Width Modulation Solenoid Valve T, E 10-12 Ω 13-15 Ω Greater than 250 K Ω Pressure Control Solenoid Valve C, D 3-5 Ω 5-6 Ω Greater than 250 K Ω Automatic Transmission Input Speed Sensor S, V 820-1020 Ω 1132-1428 Ω Greater than 250 K Ω Automatic Transmission Fluid Temperature Sensor * M, L 3164-3867 Ω 225-285 Ω Greater than 10 M Ω Vehicle Speed Sensor A, B

VSS CONN1650-2200 Ω 2360-3180 Ω @ 150°C (302°F) Greater than 10 M Ω * The resistance of this device changes rapidly with temperature.

Fluid Capacity Specifications

Application Specification Metric English Bottom Pan Removal 7.0 liters 7.4 quarts Complete Overhaul 9.5 liters 10.0 quarts Dry 12.7 liters 13.4 quarts

Case Side Cover Bolts

(56) Side Cover Bolt/Screw M8 X 1.25 X 25.0 (9) (57) Side Cover Bolt/Screw M8 X 1.25 X 21.0 (4) (58) Side Cover Bolt/Screw M8 X 1.25 X 24.0 (4)

Oil Pump Bolts

(374) Control Valve Body Bolt/Screw M6 X 1.0 X 65.0 (3) (375) Control Valve Body Bolt/Screw M6 X 1.0 X 60.0 (3) (376) Control Valve Body Bolt/Screw M6 X 1.0 X 30.0 (1) (377) Control Valve Body Bolt/Screw M6 X 1.0 X 45.0 (2) (378) Control Valve Body Bolt/Screw M6 X 1.0 X 55.0 (3) (379) Control Valve Body Bolt/Screw M6 X 1.0 X 95.0 (1) (380) Control Valve Body Bolt/Screw M8 X 1.0 X 90.0 (1) (381) Control Valve Body Bolt/Screw M6 X 1.0 X 20.0 (2) (384) Control Valve Body Bolt/Screw M6 X 1.0 X 85.0 (1)

Case Cover Bolts

(433) Case Cover Bolt/Screw TORX® Plus Special M6 X 1.0 X 32.0 (1) (434) Case Cover Bolt/Screw M6 X 1.0 X 40.0 (3) (435) Case Cover Bolt/Screw M8 X 1.25 X 50.0 (3) (436) Case Cover Bolt/Screw M6 X 1.0 X 30.0 (3) (805) Case Cover Bolt/Screw M6 X 1.0 X 16.0 (1)

Case Cover Assembly

(401) Case Cover (402) Manual Valve Link (403) Manual Valve Link Spring (404) Manual Valve (405) Low Blow Off Ball Valve Bore Plug (406) Low Blow Off Ball Valve Spring (409) Left Side Axle Oil Seal Assembly (410) Control Valve Body Alignment Sleeve (411) Bore Plug (411) Bore Plug (412) Orificed Cup Plug (414) Actuator Feed Limit Valve (415) Actuator Feed Limit Valve Spring (416) Actuator Feed Limit Valve Spring Retainer (417) Ball Valve Bore Plug (418) TCC Blow Off Ball Valve Spring (420a) Low Blow Off Ball Valve (420b) TCC Blow Off Ball Valve (421) 3-4 Accumulator Piston Cylinder (422) 3-4 Accumulator Piston Cylinder O-Ring Seal (423) 3-4 Accumulator Piston Outer Spring (424) 3-4 Accumulator Piston Inner Spring (426) 3-4 Accumulator Piston Pin (427) 3-4 Accumulator Piston Oil Seal Ring (428) 3-4 Accumulator Piston (429) Case Cover Lower Gasket (430) Case Cover Upper Gasket (431) Front Wheel Drive Shaft Bearing Assembly (432) Fourth Clutch Shaft Thrust Washer (440) Input Speed Sensor Assembly (441) Input Speed Sensor Clip (514) Drive Sprocket/Case Cover Thrust Washer (526) Case Cover Dowel Pin (526) Case Cover Dowel Pin

Oil Pump Assembly

(201) Pump Cover (202) Oil Pump Body (205) Oil Pump Cover Bolt/Screw M6 X 1.0 X 20.0 (1) (209) Oil Pump Vane Ring (209) Oil Pump Vane Ring (210) Oil Pump Selective Rotor (211) Oil Pump Selective Vane (212) Oil Pump Slide Oil Seal Ring (213) Oil Pump Slide O-Ring Seal (214) Oil Pump Selective Slide (215) Oil Pump Slide Pivot Pin (219) Oil Pump Outlet Screen Assembly (220) Oil Pump Slide Seal (221) Oil Pump Slide Seal Support (222) Oil Pump Prime Outer Spring (223) Oil Pump Prime Inner Spring

Control Valve Body Assembly (1 Of 2)

(301) Control Valve Body Machined (302) Line Boost Valve and Bushing Retainer (303) Line Boost Valve Bore Plug (304) Line Boost Valve (305) TCC PWM Solenoid Valve O-Ring Seal (306) TCC PWM Solenoid Valve O-Ring Seal (307) Pressure Control Solenoid Valve O-Ring Seal (309) Reverse Boost Valve Bushing (310) Reverse Boost Valve (311) Pressure Regulator Valve Spring Outer (312) Pressure Regulator Valve Inner Spring (313) Pressure Regulator Valve (314d) 1-2, 3-4 Shift Solenoid Valve Retainer (314e) Pressure Control Solenoid Valve Retainer (314f) TCC PWM Solenoid Valve Retainer (314g) TCC Regulator Apply Valve Bore Plug Retainer (315a) 1-2, 3-4 Shift Solenoid Valve Assembly (316a) 1-2, 3-4 Shift Solenoid Valve O-Ring Seal (316b) Pressure Control Solenoid Valve O-Ring Seal (317) 1-2 Shift Valve Spring (318) 1-2 Shift Valve (320) Torque Signal Regulator Valve Spring (321) Torque Signal Regulator Valve (322) Pressure Control Solenoid Valve Assembly (323) Line Pressure Relief Valve Spring (324) Line Pressure Relief Valve (325) Line Pressure Relief Valve Spring Retainer (326) TCC Regulator Apply Valve Spring (327) TCC Regulator Apply Valve (328) TCC Regulator Apply Valve Bore Plug O-Ring Seal (329) TCC Regulator Apply Valve Bore Plug (334) TCC PWM Solenoid Valve Assembly (335) TCC Control Valve (336) TCC Control Valve Spring

Control Valve Body Assembly (2 Of 2)

(301) Machined Control Valve Body (314a) 1-2 Accumulator Valve Retainer (314b) 4-3 Manual Downshift Valve Retainer (314c) 2-3 Shift Solenoid Valve Retainer (315b) 2-3 Shift Solenoid Valve Assembly (316) O-Ring Seal (339) 1-2 Accumulator Valve Bore Plug (340) 3-4 Accumulator Valve Spring (341) 3-4 Accumulator Valve (342) 2-3 Accumulator Valve Bore Plug Retainer (343) 2-3 Accumulator Valve Bore Plug (344) 2-3 Accumulator Valve (345) 2-3 Accumulator Valve Bushing (346) 2-3 Accumulator Valve Spring (350) 1-2 Accumulator Valve (351) 1-2 Accumulator Valve Spring (353) 3-2 Manual Downshift Valve Retainer (354) 3-2 Manual Downshift Valve Bore Plug (355) 3-2 Manual Downshift Valve Spring (356) 3-2 Manual Downshift Valve (357) 2-3 Shift Valve (359) 4-3 Manual Downshift Valve Bore Plug (360) 4-3 Manual Downshift Valve (361) 4-3 Manual Downshift Valve Spring (362) 3-4 Shift Valve (385) 2-3 Accumulator Valve Bushing Assembly Retainer

Fastener Tightening Specifications

Description of Usage Specification Metric English 2-1 Servo to Case 25 N·m 18 lb ft Accumulator Cover to Case 12 N·m 106 lb in Case Cover to Case 12 N·m 106 lb in Case Cover to Case 12 N·m 106 lb in Case Cover to Driven Sprocket Support 25 N·m 18 lb ft Case Cover to Driven Sprocket Support (TORX®) 12 N·m 106 lb in Case to Drive Sprocket Support 25 N·m 18 lb ft Case Extension to Case 36 N·m 26 lb ft Case Side Cover to Case 25 N·m 18 lb ft Case Side Cover to Case (Stud) 25 N·m 18 lb ft Case Side Cover to Case (TORX® Special) 25 N·m 18 lb ft Detent Spring to Case Cover 12 N·m 106 lb in Forward Band Servo Cover to Case 12 N·m 106 lb in Manual Shaft/Detent Nut 32 N·m 23 lb ft Oil Cooler Quick Connector 38 N·m 28 lb ft Oil Cooler Quick Connector with Checkball 38 N·m 28 lb ft Oil Pan to Case 14 N·m 10 lb ft Oil Pressure Test Hole Plug 12 N·m 106 lb in Pump Body to Case 16 N·m 11 lb ft Pump Cover to Case Cover 12 N·m 106 lb in Pump Cover to Pump Body 8 N·m 70 lb in Speed Sensor to Case 12 N·m 106 lb in TFP Switch to Case 16 N·m 11 lb ft TFP Switch to Case Cover 12 N·m 106 lb in TFP Switch to Valve Body 8 N·m 70 lb in Valve Body to Case 12 N·m 106 lb in Valve Body to Case 12 N·m 106 lb in Valve Body to Case Cover 12 N·m 106 lb in Valve Body to Case Cover 12 N·m 106 lb in Valve Body to Case Cover (TORX®) 12 N·m 106 lb in Valve Body to Driven Sprocket Support 25 N·m 18 lb ft

Last edited by 02NavyBlue; 09-26-2013 at 10:24 PM.

Is the PCS the most likely reason a tranny would hard shift?

Got petty far in about 3 and a half hours of work. I had a bit of trouble with a few little things, but nothing that slowed me down any more than 10 minutes or so. I also had to buy a 36mm socket because apparently I have aftermarket wheel hubs. I just got to work unbolting stuff like I had done it lots of times before. It was really easy so far, I don't know how anyone could call it hard, it just takes a bit of time. I had lots of advice before attempting, thanks to you guys. The only thing that had to be removed that I didn't know about was the shift linkage, it was being strained so I took off the clip that holds it to the fender. I also removed the rubber mounts on the left muffler to let the exhaust kind of slant with the engine so I don't wreck my flex pipe. Instead of dropping the trans pan to drain some fluid, I ran the engine with the return line off into a gallon container until it was full. A gallon out should be enough, if not I'll just let it drain in a catch pan with the side cover off. It may since it will be on an angle.

The next step literally is to take the side cover bolts off, that will be for tomorrow.

Last edited by 02NavyBlue; 09-27-2013 at 09:01 PM.

Well I've got the channel plate back in, next is the side cover. One question though, is it normal that when sliding the channel plate on the trans, the side by the output shaft doesn't seat completely flush like the left side, until you tighten the bolts? It had about a quarter inch gap after pushing it on the trans. It didn't take much effort to tighten the bolts and make it flush, but I wasn't sure if it's normal or not. I was thinking it's the thrust washer on the 4th hub. I pushed the hub in completely though, even used a rubber mallet and hit it all around to be sure.

Last edited by 02NavyBlue; 09-28-2013 at 07:25 PM.

| « Previous Thread | Next Thread » |

| Tags for this Thread |